Issue

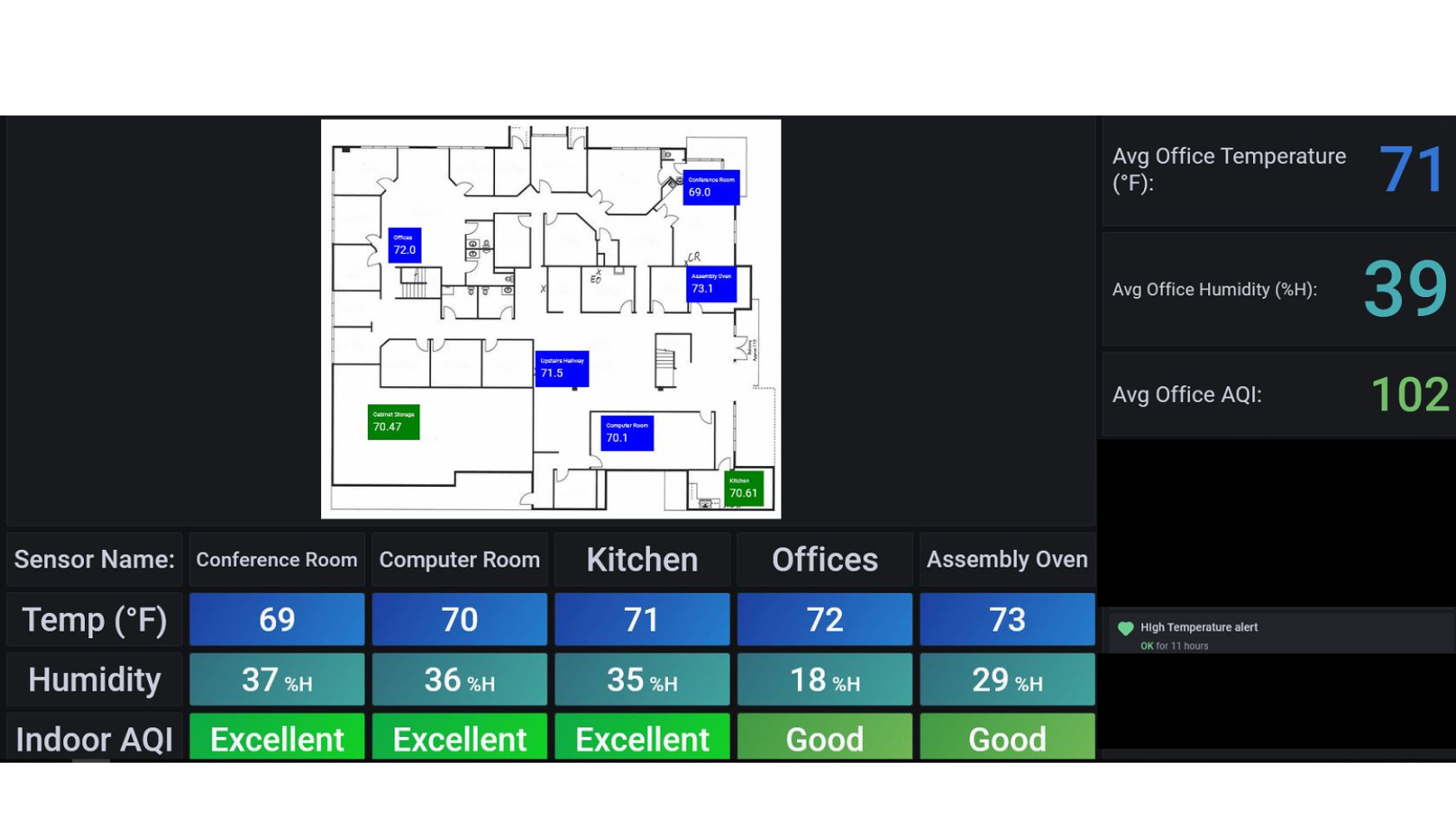

Manufacturer wanted to confirm minimum time required for burn-in is followed every time without ‘door opens,’ which was causing failures.

Solution

Burn-In Oven was instrumented with environmental sensors and door open sensor. App requires operator to log each run.

ROI

Manufacturer learned that minimum burn-in time was actually over an hour less than initially thought required if door remained closed the entire run. So, manufacturer was able to decrease burn-in time, which sped up completion and reduced energy consumption. Manufacturer was also able to track door opens that contributed to board failures.

Outcome

Decrease in product waste, energy usage and production time