Description

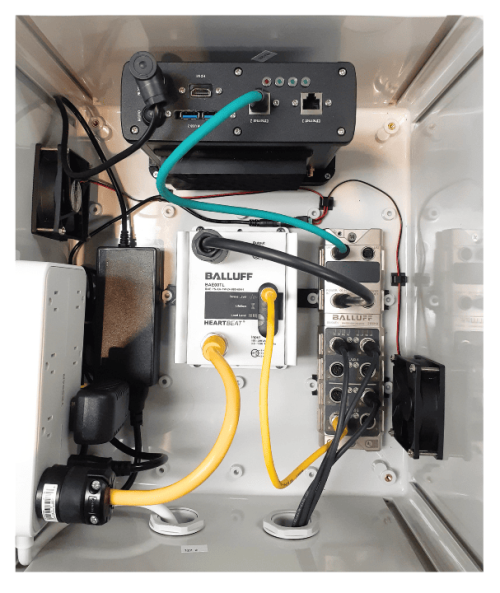

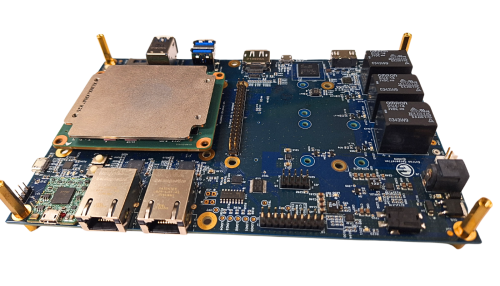

The Edge Node is a self-contained system enclosed in a NEMA box that collects, formats and streams sensor data to the Cloud. In other words, it bridges OT-IT networks, as well as acts as a gateway to connect to the Cloud making it an ideal plug-and-play solution for asset, process and people monitoring on the factory floor, in warehouses, outdoors and in other harsh environments. The Edge Node can connect to thousands of industrial-grade sensor options. Because of all of its features, Ectron’s Edge Node is an ideal NO CODE solution for data collection and formatting for manufacturers, systems integrators and software data analytics service providers. Moreover, paired with Sensors-as-a-Service℠, users also get a NO CODE solution for streaming and visualizing the data collected.

Ectron can pre-configure your Edge Node to work with new or previously installed sensors based on its intended application. Ectron also provides implementation support to end users and systems integrators.

DATA COLLECTED CAN BE USED TO:

- Remotely monitor assets, operations, operators, and production schedules

- Improve product quality and yield (with anomaly detection, AI and ML capabilities)

- Increase production capacity

- Reduce OPEX by pinpointing inefficiencies, and highlighting potential efficiencies

- Schedule machine availability

- Get real-time equipment deviation insights

- Support predictive maintenance programs

- Support sustainability programs