Issue

Agri-company had a large hops-drying bed that was not drying product uniformly.

Solution

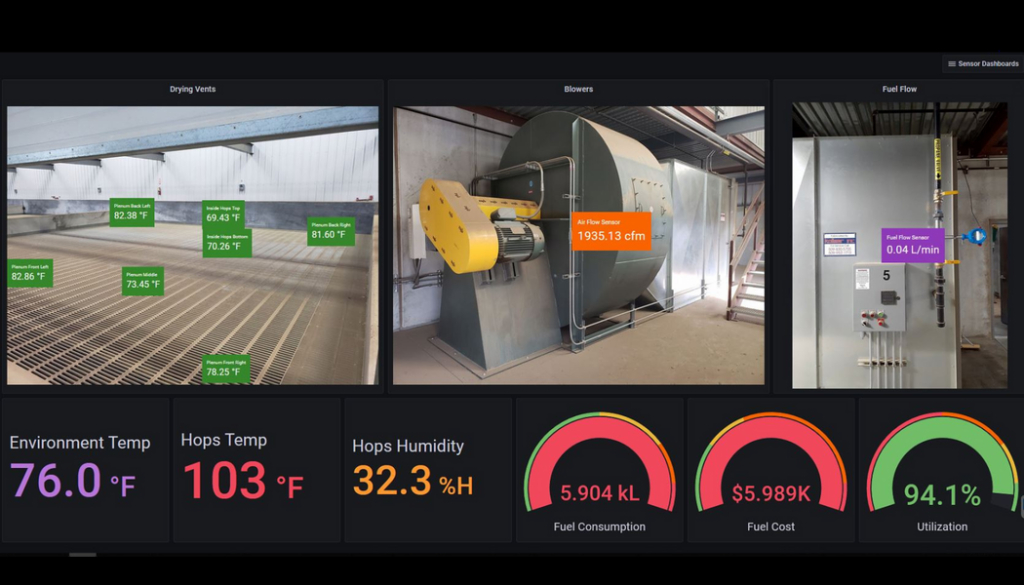

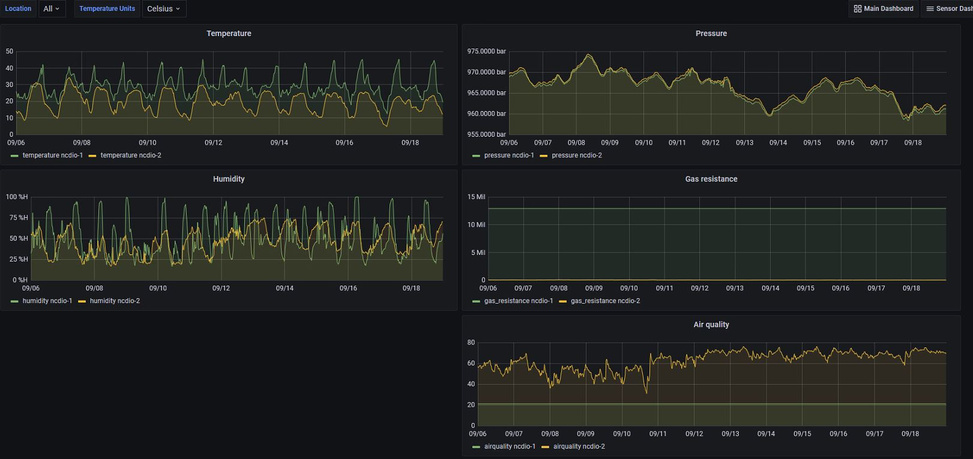

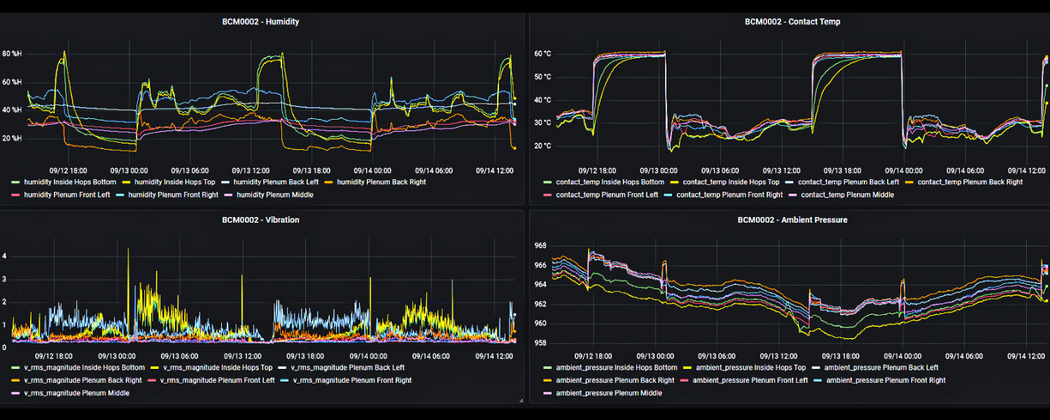

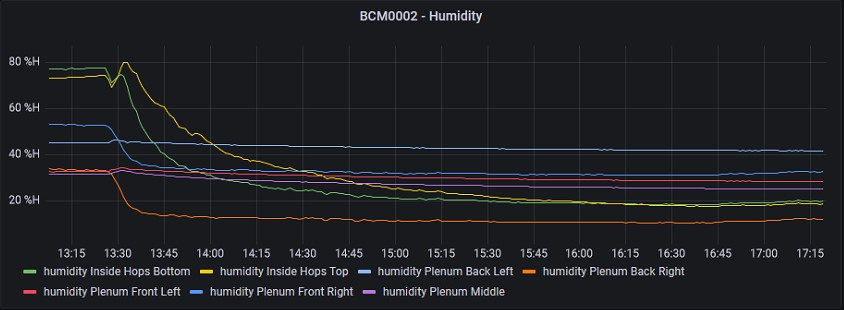

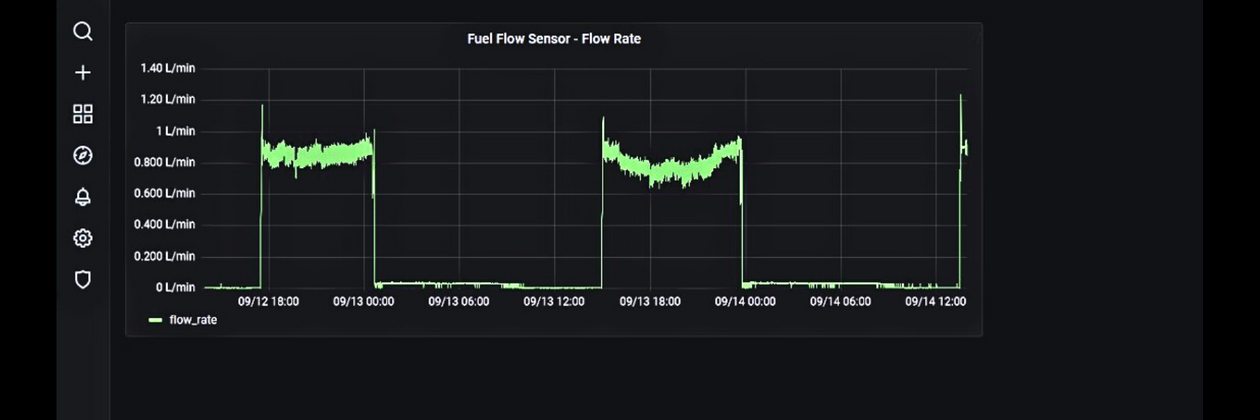

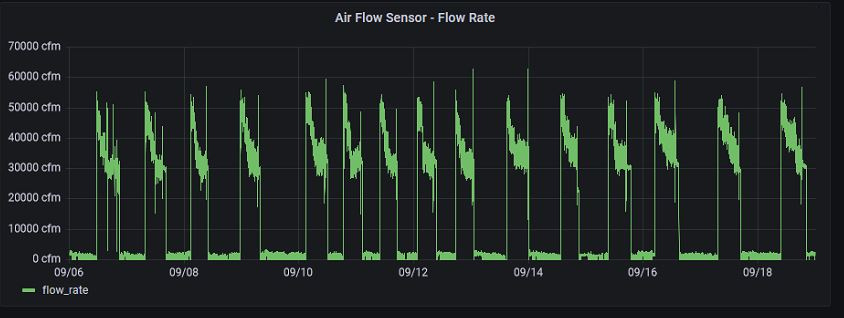

We instrumented the drying bed with a dozen industrial-grade multi-function sensors. We also added sensors to measure material temperature and humidity, airflow from fans, natural gas and electricity usage, machine utilization and availability and other KPIs. We also instrumented the area with environmental sensors to track environmental conditions that affect the bed’s temperature and, thus, product quality.

Outcome

Company has data needed to:

- Adjust machine settings (incl. fan speed) in “REAL- TIME” to get desirable average temperature across the entire bed;

- Adjust controllable environmental factors as needed “during the production run” to maintain ideal conditions;

- Test product dryness in REAL-TIME and across the entire bed;

- Forecast exact costing per run including natural gas and energy usage;

- Pinpoint equipment deviations for targeted predictive maintenance and/or repairs; and

- Run simulations to see what changes in the process yield efficiencies.

ROI

Drying time decreased by 4%. Machine warm- up time decreased by 20 minutes.