Issue

Gear manufacturer had both new and old CNC machines. Some machines were working better for certain products than others. Moreover, the older machines had substantial downtime for repairs.

Solution

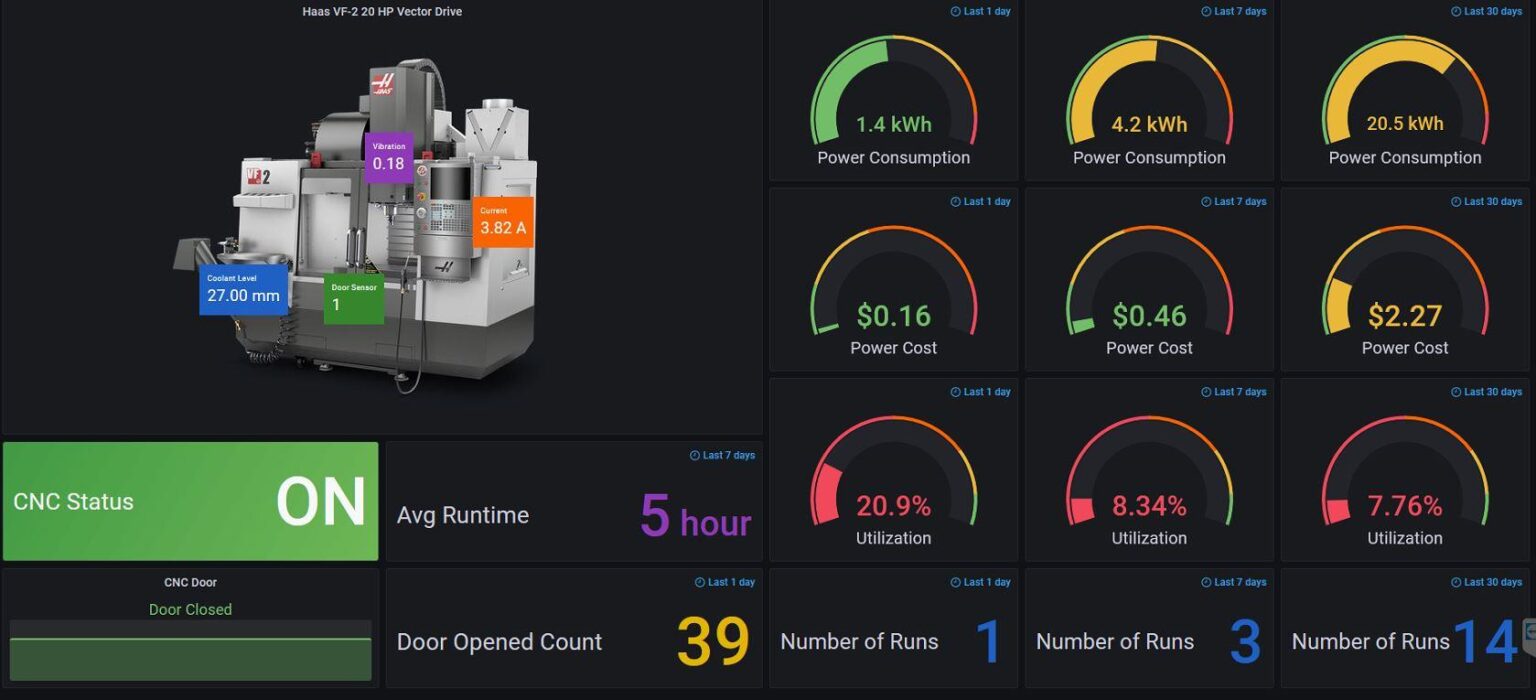

CNC machines instrumented with industrial-grade multi-function sensors. Specifically, we added sensors to measure coolant level, spindle/table vibration, type of material used and tool use turnover among other features. Operator alerts were also programmed so that production process and/or machine profile deviations could be corrected in real-time.

ROI

Customer has the data needed to identify and immediately remediate any production or machine profile deviations including vibration profile deviations, incorrect tool mounting, coolant depletion and/or maintenance omissions. Customer was also able to compare output, product quality and energy cost from machine to machine, as well as pinpoint equipment deviations for targeted predictive maintenance and/ or repairs.

Outcome

Decrease in product waste and machine downtime.