Issue

Injection molding manufacturer had both new and old machines. Some machines were working better for certain materials. The older machines had substantial downtime for repairs. Product output was different from run to run resulting in waste, and the source of the deviations could not be pinpointed.

Solution

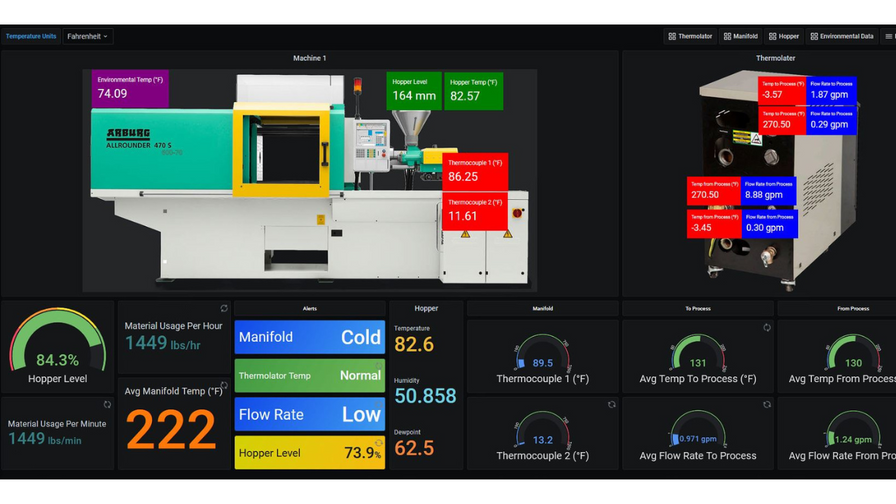

We instrumented the older injection molding machines with industrial-grade multi-function sensors. Specifically, we added sensors to measure thermolater flow rate, hopper level, manifold temperature, fluid temperature (to and from the manifold), material flow rate, material dew point, machine utilization and availability and other KPIs.

Outcome

Customer has the data needed to:

- Adjust machine settings in “REAL- TIME” to get desired manifold and hopper temperature maintained in every machine;

- Compare output and product quality from machine to machine to determine which machines worked best with what materials;

- Monitor machine usage for production scheduling and energy efficiency;

- Forecast and track per run production cost (including energy cost);

- Pinpoint equipment deviations for targeted predictive maintenance and/ or repairs; and

- Run simulations to see what changes in the process yield efficiencies.

ROI

Customer is able to reduce waste (product and time), deliver a more consistent product, implement more accurate scheduling and perform preventive maintenance on machines.