Industrial Automation Solution Helps Transform SMBs

IIoT is emerging as a force in manufacturing, but it’s primarily relegated to large companies with large budgets and well-trained staff. Ectron and Arrow Electronics team up to bring smart manufacturing and industrial automation to small and mid-size enterprise customers.

The Industrial Internet of Things (IIoT) is an emerging market, mostly relegated to large companies, with deep pockets and tech support teams to navigate the installation and management of an IIoT system. The benefits of IIoT can be profound, and they can be acutely impactful to small and mid-size enterprises.

However, those same companies are slow to adopt IIoT solutions. “Ninety-five to 98 percent of that market has not installed anything [IIoT],” says Gautam Kavipurapu, chief operating officer and vice president of engineering at Ectron Corporation.

Small to mid-size enterprises and mom-and-pop shops typically operate lean businesses. They usually don’t have a comprehensive IT team, nor can they maintain the entire stack across their operations.

Plug-and-Play IIoT

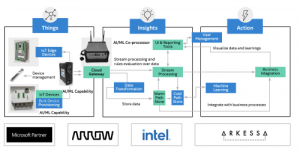

Cognizant that customers couldn’t do the integration, Ectron built the system to be plug-and-play. Ectron started in calibration and instrumentation and later realized it could capitalize on the sensor data it was collecting. The result is SmartEYE™, an end-to-end solution with artificial intelligence on the edge that enables sub-10ms response times. That’s the market Ectron is focusing on.

Ectron’s SmartEYE™ solution allows companies to integrate IIoT in their existing facilities without overhauling equipment or extensive work stoppage. SmartEYE™ is an overlay platform-as-a-service solution that uses sensors, edge analytics, artificial intelligence, machine learning, and cloud connectivity to automate factory floors.

Ectron’s SmartEYE™ solution allows companies to integrate IIoT in their existing facilities without overhauling equipment or extensive work stoppage. SmartEYE™ is an overlay platform-as-a-service solution that uses sensors, edge analytics, artificial intelligence, machine learning, and cloud connectivity to automate factory floors.

Sensors collect data at every point in the operation: at a machine, a manufacturing line, a specific cell, or the entire plant. Industrial Automation Solution Helps Transform SMBs

IIoT is emerging as a force in manufacturing, but it’s primarily relegated to large companies with large budgets and well-trained staff. Ectron and Arrow Electronics team up to bring smart manufacturing and industrial automation to small and mid-size enterprise customers.

The Industrial Internet of Things (IIoT) is an emerging market, mostly relegated to large companies, with deep pockets and tech support teams to navigate the installation and management of an IIoT system. The benefits of IIoT can be profound, and they can be acutely impactful to small and mid-size enterprises.

However, those same companies are slow to adopt IIoT solutions. “Ninety-five to 98 percent of that market has not installed anything [IIoT],” says Gautam Kavipurapu, chief operating officer and vice president of engineering at Ectron Corporation.

Small to mid-size enterprises and mom-and-pop shops typically operate lean businesses. They usually don’t have a comprehensive IT team, nor can they maintain the entire stack across their operations.

Plug-and-Play IIoT

Cognizant that customers couldn’t do the integration, Ectron built the system to be plug-and-play. Ectron started in calibration and instrumentation and later realized it could capitalize on the sensor data it was collecting. The result is SmartEYE™, an end-to-end solution with artificial intelligence on the edge that enables sub-10ms response times. That’s the market Ectron is focusing on.

Ectron’s SmartEYE™ solution allows companies to integrate IIoT in their existing facilities without overhauling equipment or extensive work stoppage. SmartEYE™ is an overlay platform-as-a-service solution that uses sensors, edge analytics, artificial intelligence, machine learning, and cloud connectivity to automate factory floors.

Ectron’s SmartEYE™ solution allows companies to integrate IIoT in their existing facilities without overhauling equipment or extensive work stoppage. SmartEYE™ is an overlay platform-as-a-service solution that uses sensors, edge analytics, artificial intelligence, machine learning, and cloud connectivity to automate factory floors.

Sensors collect data at every point in the operation: at a machine, a manufacturing line, a specific cell, or the entire plant. SmartEYE™ can assess performance, processes, personnel, and energy use. It can even monitor how environmental factors impact production, and it scales up or down to meet client needs.

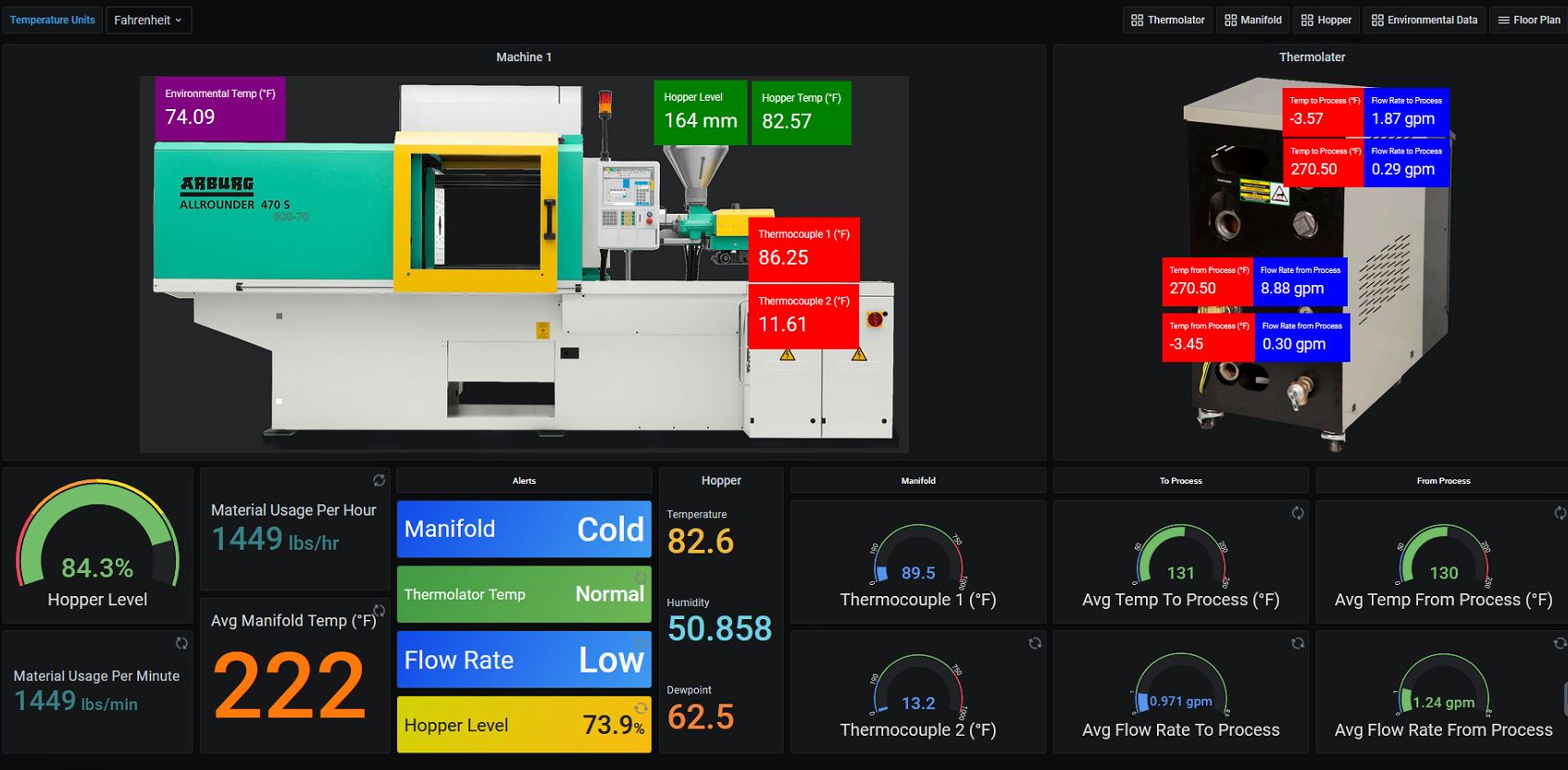

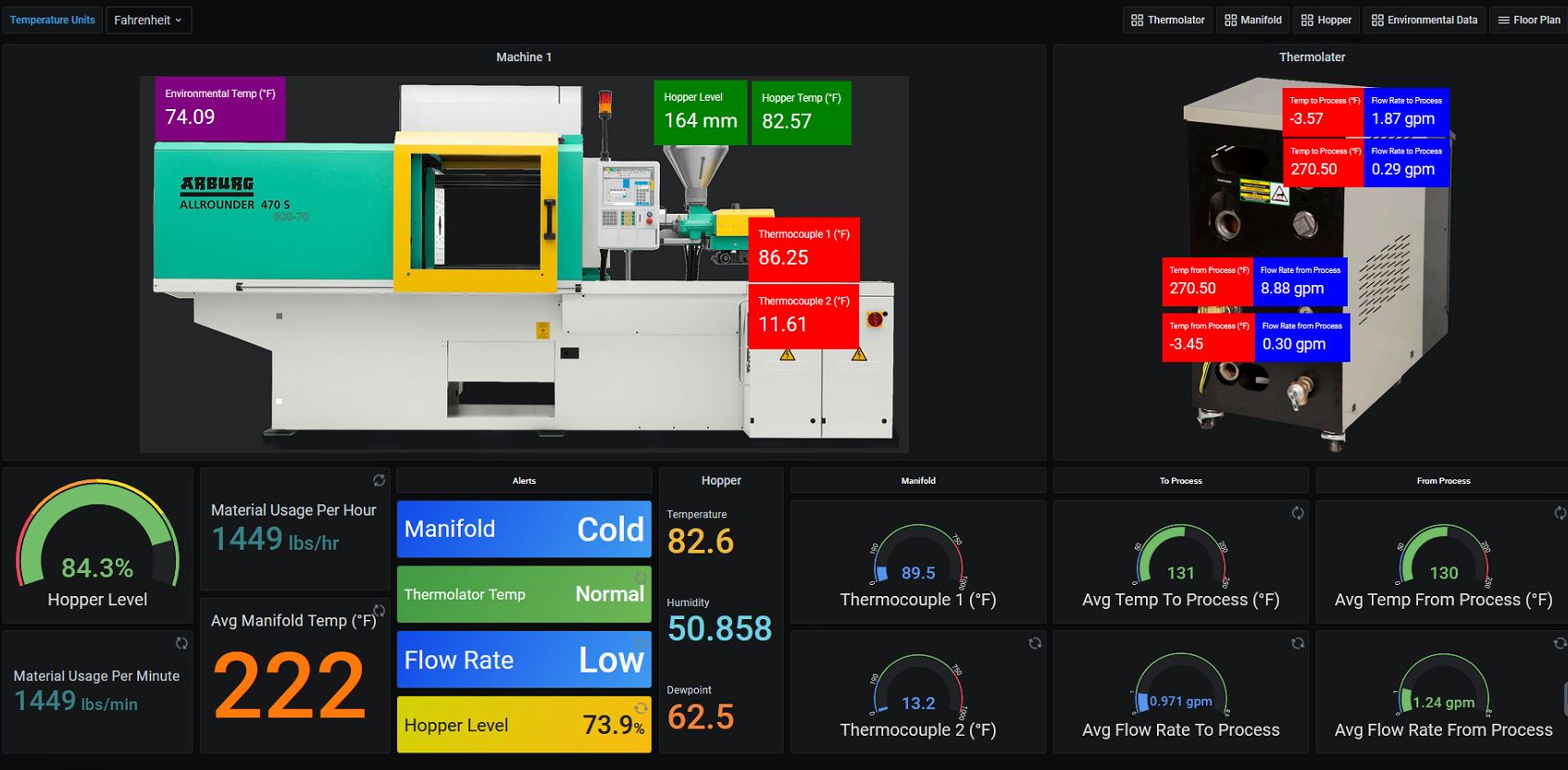

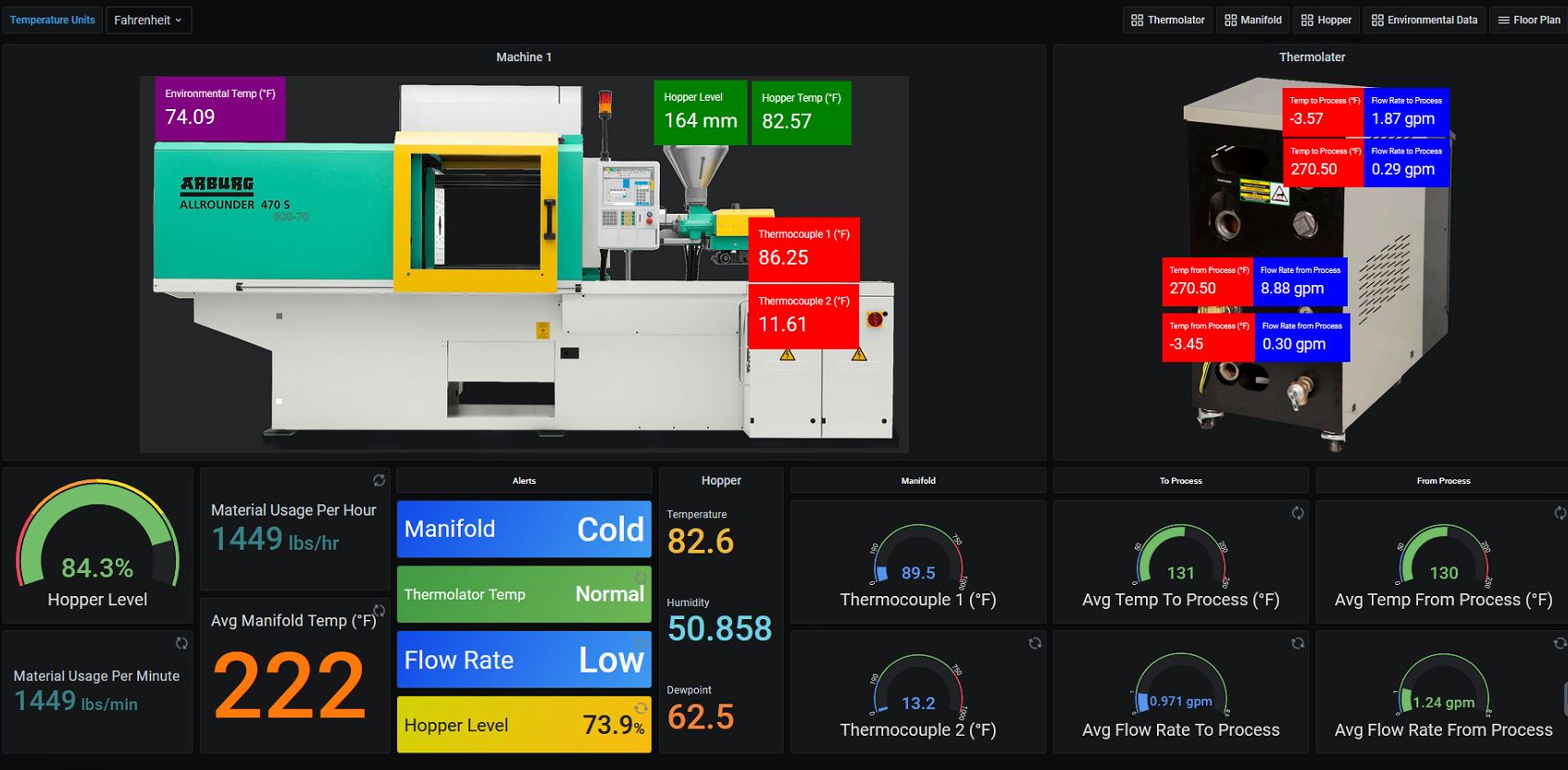

Edge-based analytics help keep costs down, too, by sending and storing only metadata in the cloud. Data is processed and analyzed at the edge, enabling real-time monitoring of hundreds of data points on a management dashboard. Customizable dashboards highlight the most relevant data for the company or project, and the system can integrate with and enhance existing MRP and ERP systems.

Ectron and Arrow collaborate with partners to determine what customers want to learn about their operations, then build unique sensor-based solutions and algorithms. Ectron coupled its device and software systems with Arrow Electronics’ edge hardware offerings. Arrow also provides system integrators with hardware and support services on a global scale.

Data Analytics for Optimum Output

The SmartEYE™ market-ready solution is designed for specific applications—injection molding and computer numerical control (CNC) machines—in vertical markets such as light manufacturing, food processing, and pharmaceuticals. SmartEYE™ can monitor processes in drying machines or ovens used to cure materials in machine shops or to bake items in food processing plants. It can ensure proper dehumidification where electronics are manufactured and stored. Additional applications and verticals are expected, including automated value-stream mapping capabilities.

One Ectron customer with an injection molding plant wanted to see how the temperature affects the quality of its products. SmartEYE™ monitored the run time, cool down time, production cycle, energy used, type of material, and other factors. It analyzed and correlated the data and found the precise manufacturing conditions, the exact cost of creating each widget, and the optimal adjustments to improve the yield during the manufacturing process.

That detail can help small and mid-size companies increase their profit margins. The key to selling in that market is education, Kavipurapu says. “They are looking for a turnkey solution, and that’s the void we fill,” he says. “They have to learn the value proposition. Whatever they spend affects their bottom line, so we have to show them: You’ll save money, or you can move more product, or you can improve product quality. It has to affect the bottom line directly.” can assess performance, processes, personnel, and energy use. It can even monitor how environmental factors impact production, and it scales up or down to meet client needs.

Edge-based analytics help keep costs down, too, by sending and storing only metadata in the cloud. Data is processed and analyzed at the edge, enabling real-time monitoring of hundreds of data points on a management dashboard. Customizable dashboards highlight the most relevant data for the company or project, and the system can integrate with and enhance existing MRP and ERP systems.

Ectron and Arrow collaborate with partners to determine what customers want to learn about their operations, then build unique sensor-based solutions and algorithms. Ectron coupled its device and software systems with Arrow Electronics’ edge hardware offerings. Arrow also provides system integrators with hardware and support services on a global scale.

Data Analytics for Optimum Output

The SmartEYE™ market-ready solution is designed for specific applications—injection molding and computer numerical control (CNC) machines—in vertical markets such as light manufacturing, food processing, and pharmaceuticals. SmartEYE™ can monitor processes in drying machines or ovens used to cure materials in machine shops or to bake items in food processing plants. It can ensure proper dehumidification where electronics are manufactured and stored. Additional applications and verticals are expected, including automated value-stream mapping capabilities.

One Ectron customer with an injection molding plant wanted to see how the temperature affects the quality of its products. SmartEYE™ monitored the run time, cool down time, production cycle, energy used, type of material, and other factors. It analyzed and correlated the data and found the precise manufacturing conditions, the exact cost of creating each widget, and the optimal adjustments to improve the yield during the manufacturing process.

That detail can help small and mid-size companies increase their profit margins. The key to selling in that market is education, Kavipurapu says. “They are looking for a turnkey solution, and that’s the void we fill,” he says. “They have to learn the value proposition. Whatever they spend affects their bottom line, so we have to show them: You’ll save money, or you can move more product, or you can improve product quality. It has to affect the bottom line directly.”

SAN DIEGO, July 14, 2020 (Newswire.com) – Ectron Corporation (

SAN DIEGO, July 14, 2020 (Newswire.com) – Ectron Corporation ( Arrow And Ectron Partnership

Arrow And Ectron Partnership

Ectron’s SmartEYE™ solution allows companies to integrate IIoT in their existing facilities without overhauling equipment or extensive work stoppage. SmartEYE™ is an overlay platform-as-a-service solution that uses sensors, edge analytics,

Ectron’s SmartEYE™ solution allows companies to integrate IIoT in their existing facilities without overhauling equipment or extensive work stoppage. SmartEYE™ is an overlay platform-as-a-service solution that uses sensors, edge analytics,