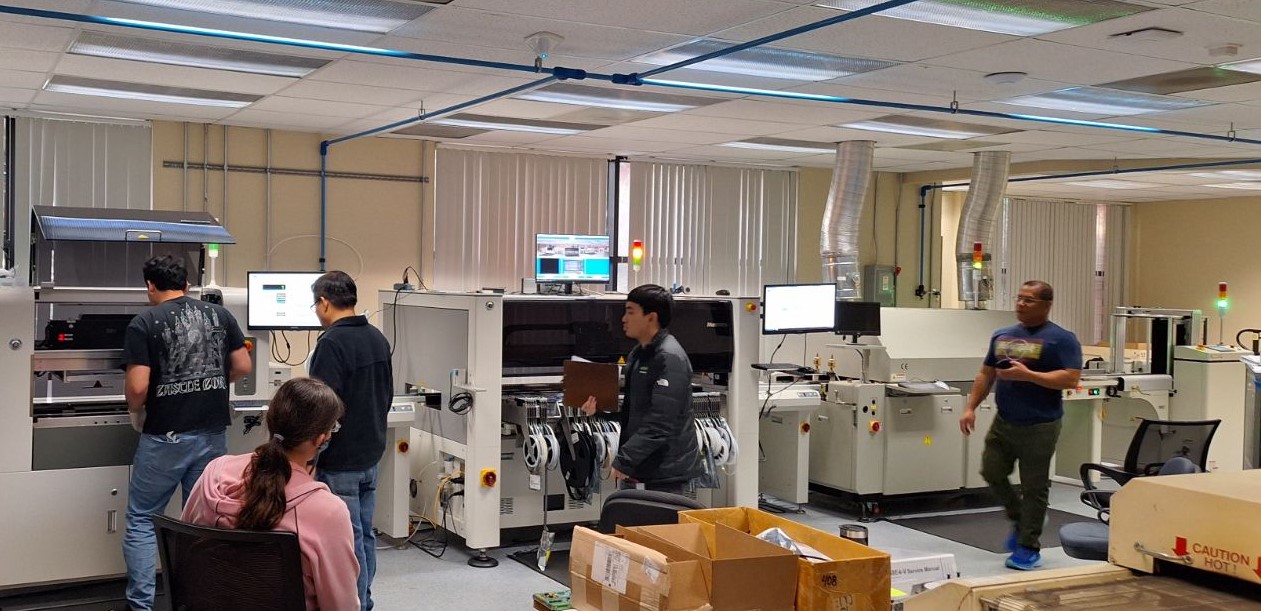

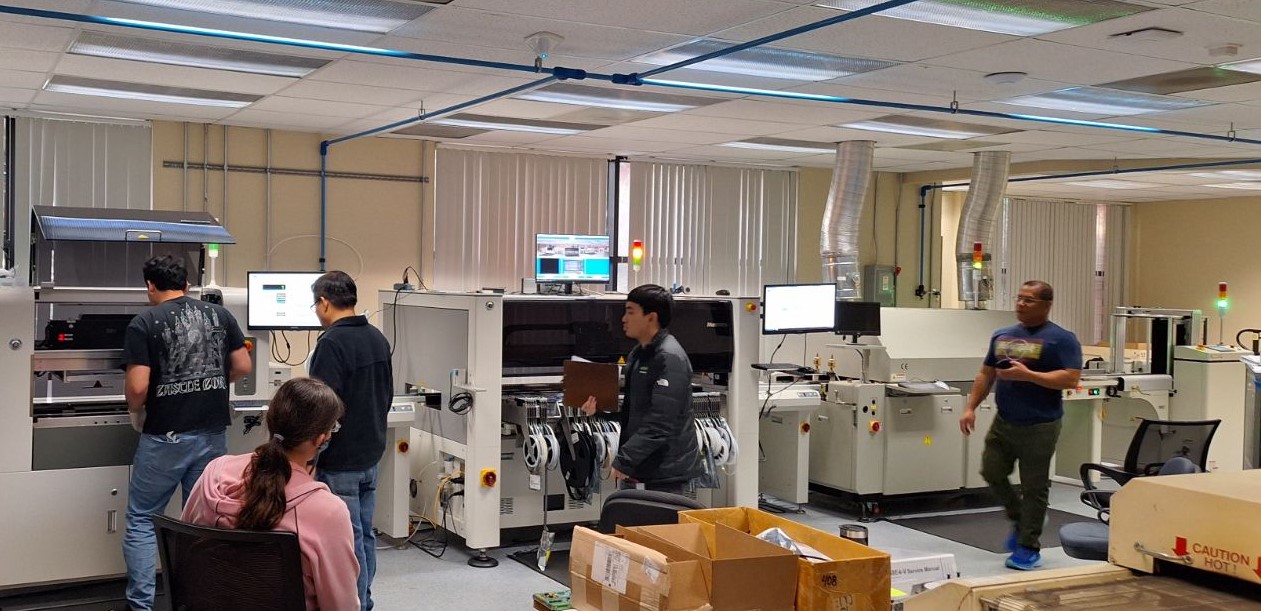

Our engineers and technicians can’t wait to Geek Out!

Our engineers and technicians can’t wait to Geek Out!

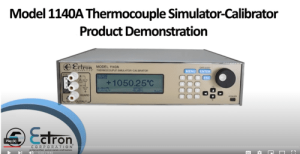

With 0.06°C Accuracy for Common Thermocouple Types, the Model 1140A is the gold standard

1140A Thermocouple Simulator-Calibrator Product Demonstration – YouTube

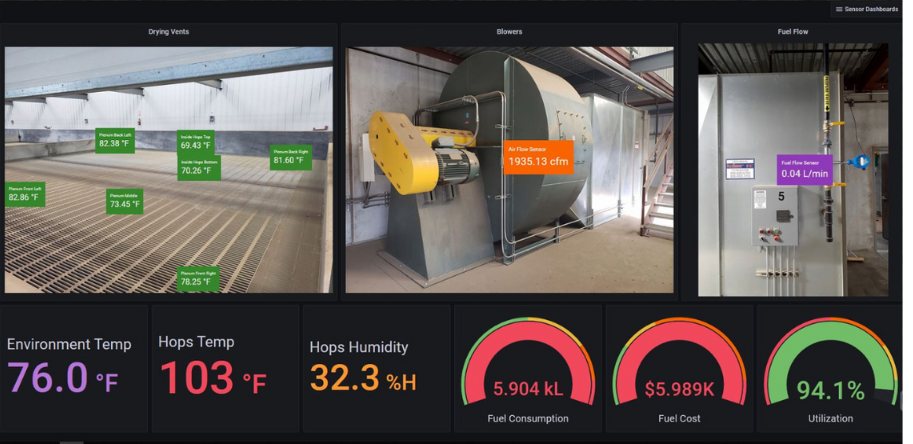

Using SmartEYE™, this Hops Drying Facility has optimized its operations and equipment. Installation on a remote farm was no problem for the Ectron team.

Thanks to its factory and equipment monitoring PaaS, SmartEYE™, Ectron Corporation has been selected to join an elite #MSPartner cohort in the #CatalystAccelerator, presented by Microsoft’s @BlackChannelPartnerAlliance, @Black Partner Growth Initiative and @AppMeetup. Inclusion in the Accelerator means Ectron will have access to more resources and technology, which Ectron will use to make customer implementations of SmartEYE™ more efficient and SmartEYE™ data analytics more useful, a benefit that customers will see immediately.

“The Black Channel Partner Alliance, AppMeetup, and the Microsoft Black Partner Growth Initiative are excited to work with Ectron. [By participating in the Accelerator, Ectron has] a whole team [within Microsoft] focused on supporting Ectron’s growth goals over the next few months,” says Regina Johnson, Microsoft BPGI Director of Global Strategy. “This partnership brings even more resources and support to Ectron and, therefore, more power to U.S. manufacturers. With SmartEYE, Ectron is changing the game for U.S. manufacturing by bringing small and medium-sized manufacturers online for an affordable price. Manufacturers need to collect real-time data from the factory floor to make the best decisions regarding operations. Manufacturers that fail to transition to data-driven decision-making are putting themselves at a huge competitive disadvantage. Ectron’s SmartEYE™, a data collection and data-analytics Platform-as-a-Service made specifically for industrial use, is a great equalizer, allowing every manufacturer in the U.S. to implement all of the operational, financial and sustainability efficiencies enjoyed by multi-billion-dollar enterprises that use data analytics to run leaner and cleaner,” according to Kary Dodd, CEO of Ectron Corporation.

As part of the Microsoft #BuildFor2030 Initiative, in support of the United Nations Sustainable Development Goals, we’re continuing to highlight solutions that are enabling broader societal impact, and our partners’ journeys growing their business on the marketplace. To honor Black History Month this year, I sat down with Kary Dodd, CEO of Ectron, to hear their story and partner journey.

About Kary: After working over 20 years in the technology sector, including as General Counsel for an international IT company with over $1 Billion in annual revenues, Kary Dodd became CEO of Ectron Corporation in 2017. Under her leadership, Ectron has launched a suite of IoT computer products and solutions with AI/ML capabilities including Edge computers and its factory operations monitoring solution, SmartEYE™ Factory Flow PaaS. Ectron has also partnered with Microsoft, Intel, AMD, Arrow Electronics and Balluff to bring its IoT products and solutions to the marketplace.

About Regina: Regina Johnson is a Senior Manager at Microsoft, where she spearheads initiatives to enhance channel partner growth strategies in the Global Partner Solutions organization. In her dual roles as the Community Lead for Microsoft Partner-led Associations and the Director of Global Strategy for the Black Partner Growth Initiative, Regina develops and optimizes targeted go-to-market, sales, and business processes to cultivate strategic partnerships and advance inclusive growth.

[RJ]: Tell us about Ectron Corporation and your mission. What inspired the founding?

[KD]: My mission is to make Industry 4.0 – digital transformation leveraging the latest technologies such as cloud computing, IoT and AI -available to manufacturers of every size. Ectron manufactures its own Edge computers in-house, and so we know that in order to remain competitive we have to be efficient. Analyzing data from the factory floor is the only way to accurately pinpoint bottlenecks, eliminate inefficiencies and maximize resources. Once we implemented data-driven decision-making at Ectron with Edge computing and data analytics using Microsoft Azure, we saw that we were in a position to assist other manufacturers. The cloud has been, and will be, an extraordinary tool for entrepreneurs, allowing even small and medium-sized businesses to reach a global audience. That said, to stay competitive, businesses must run lean and be sustainable. To do this correctly, you need data and implementation of data-driven initiatives for operational savings and resource optimization. Multi-billion-dollar enterprises are already doing this, and we are proud to say that Ectron has created a way for small and medium-sized enterprises to do the same.

[RJ]: Can you tell us a bit about the application(s) you have available on the marketplace? How does it work?

[KD]: We have several applications on the Microsoft Marketplace including SmartEYE™ Factory Flow PaaS, our scalable factory monitoring solution. With Level 1 of SmartEYE™, manufacturers can monitor their production processes and schedules, human resource efficiency, component shortages and other causes for delays, in real-time for just $199/month for the entire factory. With Level 2, manufacturers can also monitor their equipment uptime/downtime and related energy cost. With Level 3, manufacturers can monitor every aspect of operations including machine functionality (for predictive maintenance), product quality and even environmental factors that may affect the production process. Moreover, with Ectron’s proprietary Edge computers running AI/ML algorithms on the Edge, and Microsoft’s Azure Cloud solutions such as ML Studio, we are able to create machine and process models that not only learn and infer, but also teach. Our solutions are extremely user-friendly. Manufacturers can go online to download the app, upload their product and production data and start monitoring operations instantly. We even have a 30-day free trial for customers to try us out at no risk.

[RJ]: What Microsoft cloud products did you use in your app development? What value is this enabling with your customers?

[KD]: We use Power Apps, Azure SQL Database, Power BI and Azure-managed Grafana to create a seamless, easy-to-use integration from the Edge to the Cloud. Microsoft’s cloud-based tools make it easy for us to offer a customized solution to our customers in just a matter of days. We always tell our customers “Let us know what data you want to see, and how you want to see it and we will customize our solution to fit your needs.” This is possible because Microsoft’s suite of cloud-based solutions has multiplied the efficiencies of our engineering team. Moreover, with the available Microsoft training modules and developer support teams, we are able to keep up with the pace of emerging technology and even influence the development of new technologies.

[RJ]: How has Microsoft supported you along your journey?

[KD]: Engaging with Microsoft has been a game-changer for Ectron. The resources we have been given to support our business go far beyond what I could have expected. We have been given access to leadership to pitch our products and services through the BPGI (Black Partner Growth Initiative); we have been given funds to grow our business through Microsoft’s Capital Fund Program; we have been given insight and invaluable advice via Microsoft’s Mentorship Program that partnered me with Jane Koh as a mentor; we have been given technical resources via Microsoft for Start-Ups Founder’s Hub; we have been given wings in terms of selling ourselves and our vision through the sales training lead by AppMeetUp during the Microsoft Catalyst Accelerator; and we have been able to turn our expertise into transactable offers thanks to ISV Success. In summary, we have been given direction, inspiration, introductions and vision by leaders of one of the most powerful companies in the world as our guides.

[RJ]: Ectron Corporation has played a valuable role to further industry innovation in manufacturing, pharmaceuticals and defense industries. Can you share how your solutions have been aligned to supporting the UN SDGs? Why is this important?

[KD]: Our solutions are aligned to several UN SDGs including: (a) Industry Innovation & Infrastructure; (b) Responsible Production; and (c) Decent Work and Economic Growth. By implementing data-driven decision making using SmartEYE™, manufacturers can do more with less, i.e. improve output, reduce waste, use less energy, create less emissions and pollutants, better support and incentivize their workforce, extend machine life and overall optimize production. We view SmartEYE™ as a great equalizer. In other words, we are giving all manufacturers (regardless of size) the ability to make data-driven decisions just like the multi-billion-dollar enterprises. According to industry reports, 94% of manufacturers want intelligent data analytics added to their operations because they know they are 23x more likely to acquire customers, 6x more likely to retain customers and 19x more likely to be profitable than operations without data-driven decision-making. For example, for a small California manufacturer, SmartEYE™ was able to reduce the Compressor Room energy cost by 82% by monitoring machine temperature in real-time and remotely running the cooling system only when needed. By measuring machine temperature, environmental temperature and product dryness, the data collected by SmartEYE™ allowed a Washington-based agri-company to reduce its hops-drying process time by 4%, which also resulted in significant energy savings. Using SmartEYE™, a large California-based logistics company virtually eliminated packing errors saving time, money and fuel costs. Moreover, by monitoring employee efficiency in real-time, they were able to reward members of their workforce who were exceeding expectations and incentivize others to do their best. Manufacturers of all sizes running leaner and more efficiently is beneficial for small and medium-sized business owners, their employees and the planet.

[RJ]: What does Black History Month mean to you? How does your organization honor Black History Month?

[KD]: Black History Month is an opportunity to reflect on the accomplishments of African-Americans in American society. It sometimes takes me aback when I realize that my mother was alive at a time when there were still separate drinking fountains, lunch counters and other accommodations in the South, yet in her lifetime she was able to become a tenured college professor at a prestigious university and was able to vote twice for an African-American president. I am always humbled by the extraordinary feats of those who faced a level of racism that I can barely begin to imagine, but in this month, those thoughts come to the forefront. While I never forget who I am, and also try not to forget that everyone has their own struggle, Black History Month is special and a time of exceptional pride because it inspires the African-American community, pays homage to generations who laid the foundation for our success in unimaginable circumstances and educates the rest of the world on the glorious strength and resilience of the human race and the possibility of justice in what often appears to be an unjust world.

[RJ]: What advice do you have for other founders and women founders looking to start new businesses or grow their careers in your field? What resources would you suggest?

[KD]: My best advice is to find one or more mentors in your industry. The energy expended trying to figure out how to do things you’ve never done before is better used promoting your business. As a business leader, I cannot emphasis enough the importance of working “on” your business rather than “in” your business. There are always internal tasks that will fall to you, but as a corporate leader championing your company to the outside world is your primary responsibility. When you have mentors, not only do you benefit from their learned advice, but you also expand your reach exponentially as they can introduce you to the network, they spent their careers building. There are several Microsoft-affiliated organizations I would highly recommend to other women founders including Women In Cloud, and BCPA. The leadership teams for each of these organizations are selflessly dedicated to helping others succeed, particularly women and persons of color.

[RJ]: What are you most proud of in your journey building/ leading Ectron? What’s next?

[KD]: I am most proud of our ability to bring a scalable IoT solution to manufacturers of all sizes. I really believe SmartEYE™ to be a great equalizer. No matter where a company is on its IoT-journey, we can help. According to several industry reports, over 90% of manufacturers realize that they will need to begin making data-driven decisions to stay competitive; however, a majority of those organizations don’t know where to start and feel as though Industry 4.0 is out of reach, even though their customers are starting to demand monitored production processes and production certifications. What we are bringing to the table is Industry 4.0 in-a-box, so manufacturers can start with a simple, practical overview of operations, then in their own time and in accordance with their own budgets, they can eventually incorporate all of the data analytics and insights enjoyed by multi-billion-dollar corporations. If a manufacturer has just $2,000/year to invest in its success, we can get them started making data-driven decisions to optimize their operations.

If you cannot find the perfect Sensor(s) here, please Schedule a Product Consultation and our experts can help you.