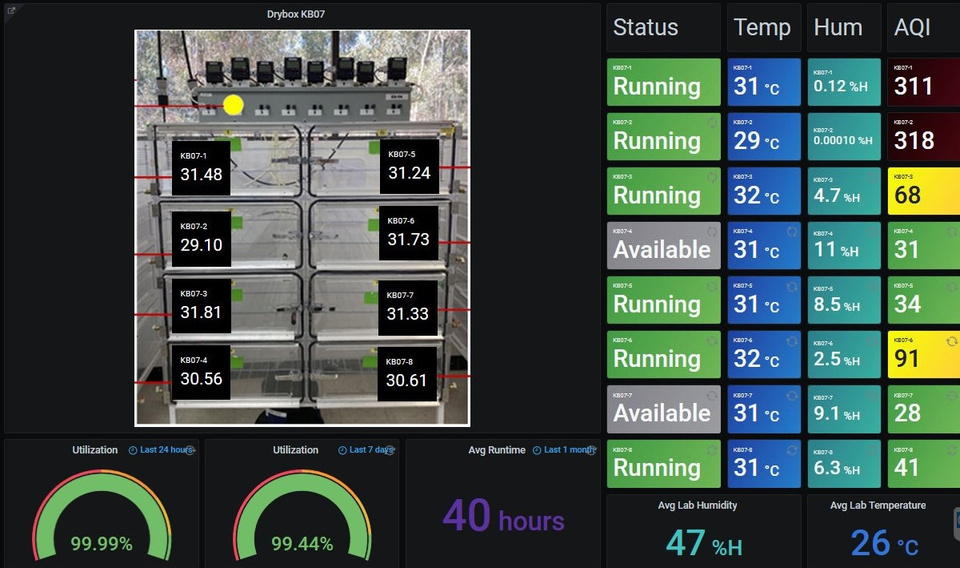

Description

With the Dry Box Market-Ready Kit, you can monitor your Dry Boxes (modern or legacy) and send all of the information to your network, ERP System or other business intelligence software. It is a NO CODE, plug-and-play solution.

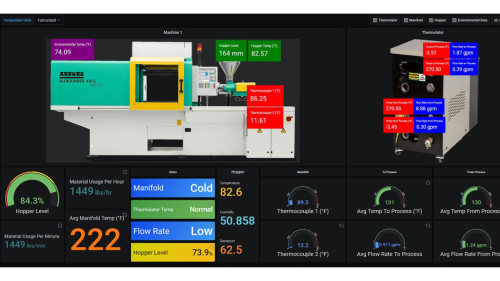

WHAT IS MONITORED

- Environmental Factors Inside Each Box (Temperature, Humidity, Pressure)

- Environmental Factors Outside Each Box (Temperature, Humidity, Pressure)

- Door Status (Open-Closed)

- Door Opens Per Run

- Job Duration

- Yield Per Job

- Cost Per Unit, Cost Per Run (Material and Energy)

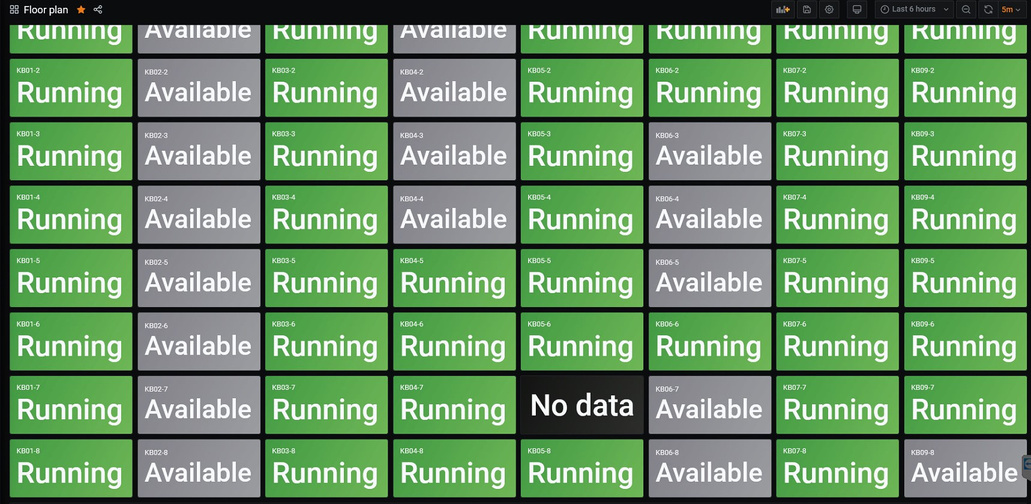

- Machine Utilization/Uptime

DATA USAGE

- Monitor equipment characteristics for anomolies.

- Compare output and product quality of various dry boxes.

- Root cause product nonconformance caused by equipment deviations.

- Pinpoint equipment deviations for predictive maintenance and repairs.

- Track environmental effects on product quality and equipment performance.

- Forecast and track per run cost (including energy cost).

- Check usage hours to trigger notification for routine maintenance.

- Run simulations to see what changes in the process yield efficiencies.

- Get OEE numbers for each machine

- Utilize energy data to support a Sustainability Program.

The data collected is so fine-grained that equipment feature deviations can be specifically targeted in real-time. Having such detailed data also assists in upgrading equipment predictive maintenance programs, as well as focused troubleshooting relating to equipment.

STANDARD CONFIGURATION

- 1 Edge Node (up to 5 Dry Boxes) or 1 Intelligent Edge Node (up to 100 Dry Boxes)

- 1 Multifunction Sensor per Dry Box

- 1 Power Sensor Module

- 1 Computer Tablet for Operator Data Entry

ADD-ONS

- Proximity Sensors for Door Open/Close Status