Description

Intelligent Edge Node: For Factory Floor Data Collection and Data Analytics on the Edge w/ AI/ML Capabilities

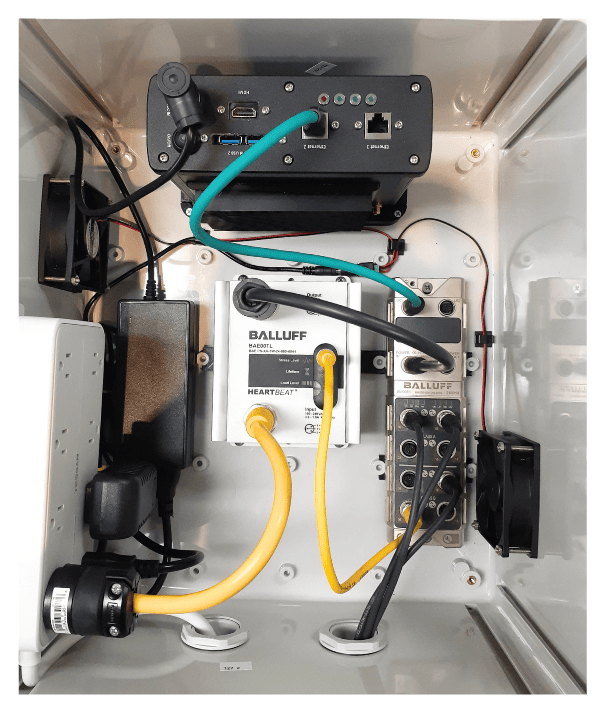

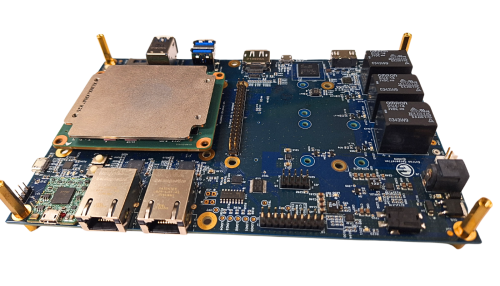

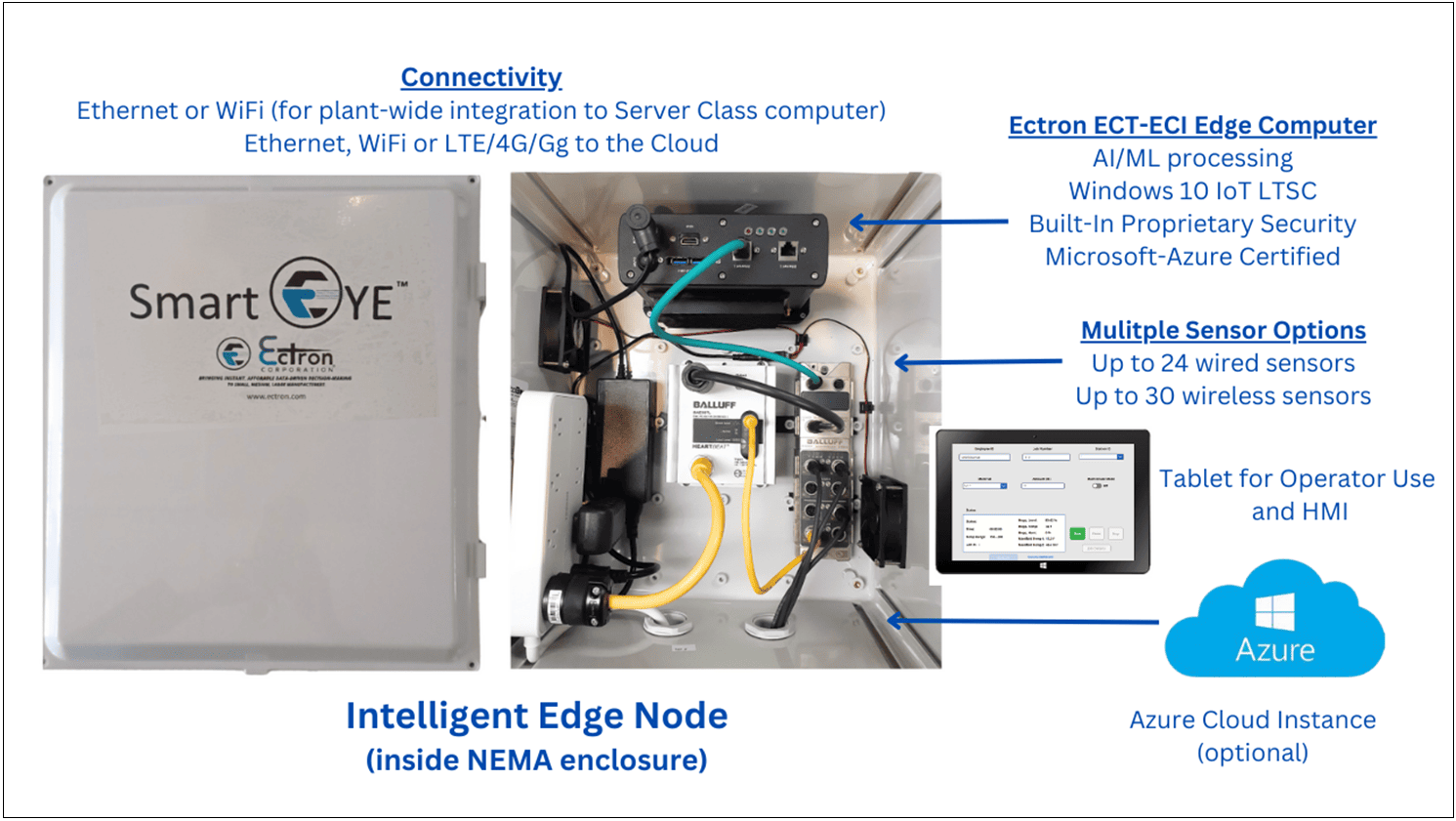

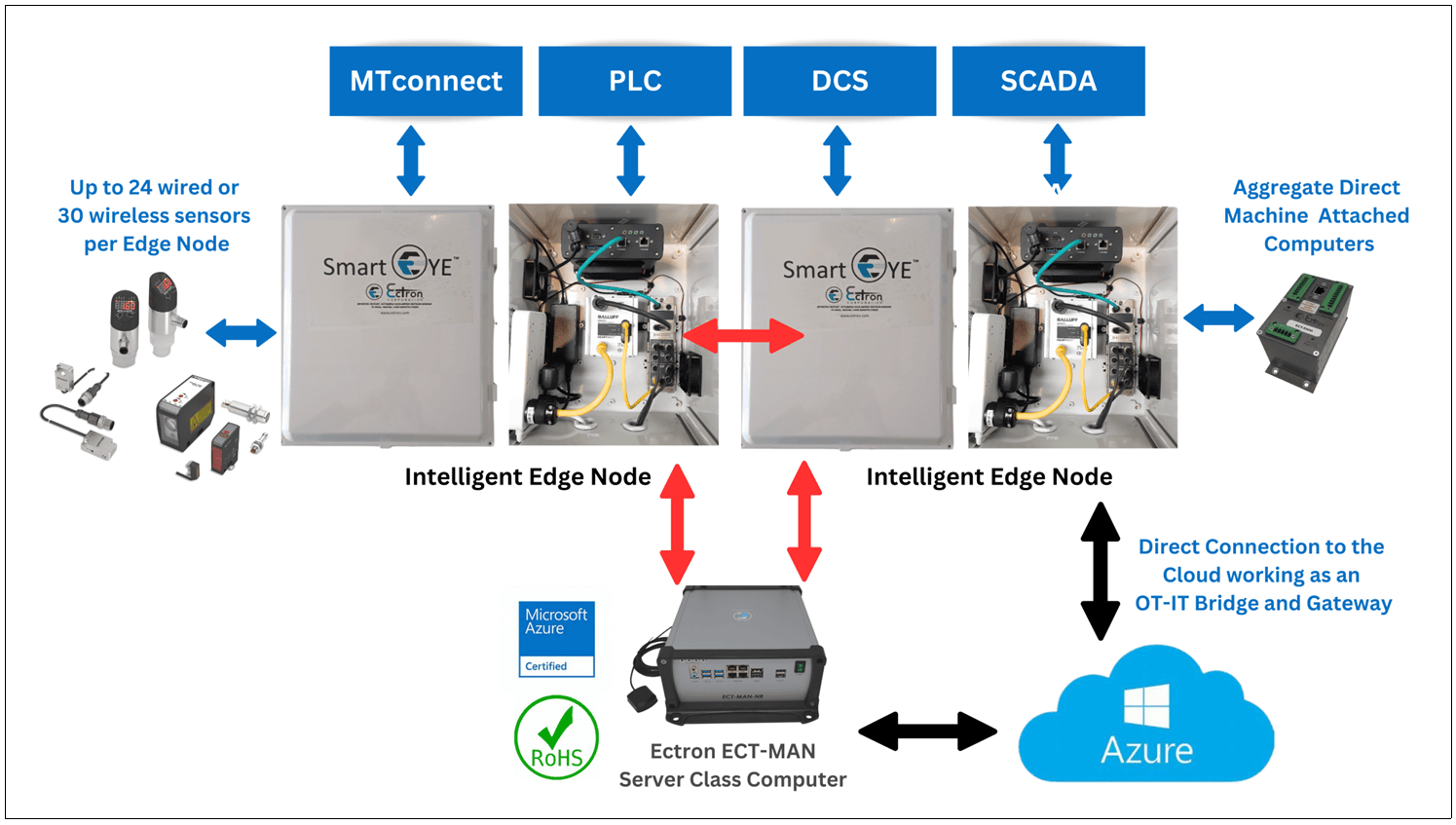

The Intelligent Edge Node is a self-contained system enclosed in a NEMA box that collects, aggregates, and analyzes data in REAL-TIME on the Edge. It is a complete hardware plus software solution for building an Intelligent Edge for asset, process, and people monitoring on the factory floor, in warehouses, outdoors, and in other harsh environments. The Intelligent Edge Node can connect to thousands of industrial-grade sensor options, as well as extract data from machines using MT Connect, DCS, PLC, and SCADA. With its AI/ML capabilities, without manual intervention, the Node builds machine/process models that evolve over time to account for machine age, machine use, operator identifiers, and other factors (rather than static models based only on manufacturer profiles). Powered by Ectron Corporation’s ruggedized Edge Computer with Artificial Intelligence and Machine Learning Capabilities (ECT-ECI), the Intelligent Edge Node is an ideal NO CODE data collection solution for manufacturers, systems integrators, and software data analytics service providers.

The Intelligent Edge Node bridges OT-IT networks, as well as acts as a gateway to connect to the Cloud. The Node is ideal for providing complete visibility of manufacturing processes and equipment functionality. It can serve as the first data aggregation point in a factory as it is compatible with thousands of wired and wireless sensor options; or aggregate data from a network of smaller computers that are collecting data from various sensors. These can be third-party computers or Ectron’s own machine-attached computers/gateways with AI/ML capability. Moreover, the Intelligent Edge Node can communicate and exchange data with other Intelligent Edge Nodes, making it infinitely expandable in terms of coverage. The Edge Computer comes with built-in hardware and software security features to protect the environment from intrusion.

The Node can be pre-configured with sensors (wired and/or wireless) based on its intended application. As such, the Node can be used in a plug-and-play fashion. Ectron also provides implementation support to end users and systems integrators.

The Intelligent Edge Node is the fundamental building block of SmartEYE™, Ectron’s Platform as a Service IoT plug-and-play solution.

TYPICAL CONFIGURATION

- IP 67 class NEMA enclosure with fans

- Sensor Hubs with the capacity of up to 24 wired and/or 30 wireless sensors

- Ectron ECT-ECI computer with 480 GB storage and AI/ML co-processor

- Power Supply

- Cellular Modem (optional) if wired Ethernet connection is not available

- Ethernet Switch

- Wireless Access point (Optional)

- Cellular Modem (optional) if wired Ethernet connection is not available

TYPICAL DEPLOYMENT ARCHITECTURES

DATA COLLECTED CAN BE USED TO:

- Remotely monitor assets, operations, operators, and production schedules

- Improve product quality and yield (with anomaly detection AI and ML capabilities)

- Increase production capacity

- Reduce OPEX by pinpointing inefficiencies, and highlighting potential efficiencies

- Schedule machine availability

- Get real-time equipment deviation insights (sub 10-millisecond response)

- Support predictive maintenance programs

- Support sustainability programs

- Fuse data from multiple sources, and aggregate into useful, real-time dashboards

- Build a secure OT network

- Build a robust learning IIoT network with AI/ML capability on the Edge