Description

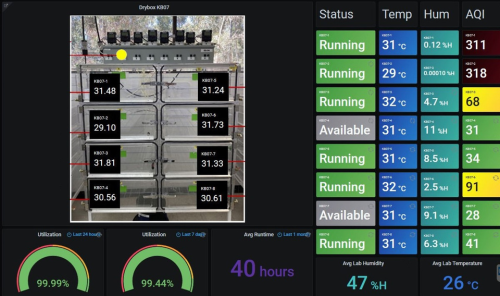

With the Optical Inspection Kit, you can monitor any portion of the production process or any product being produced for visual confirmation of compliance and/or deviations. All the data can be sent to your network, ERP System or other business intelligence software. It is a NO CODE, plug-and-play solution.

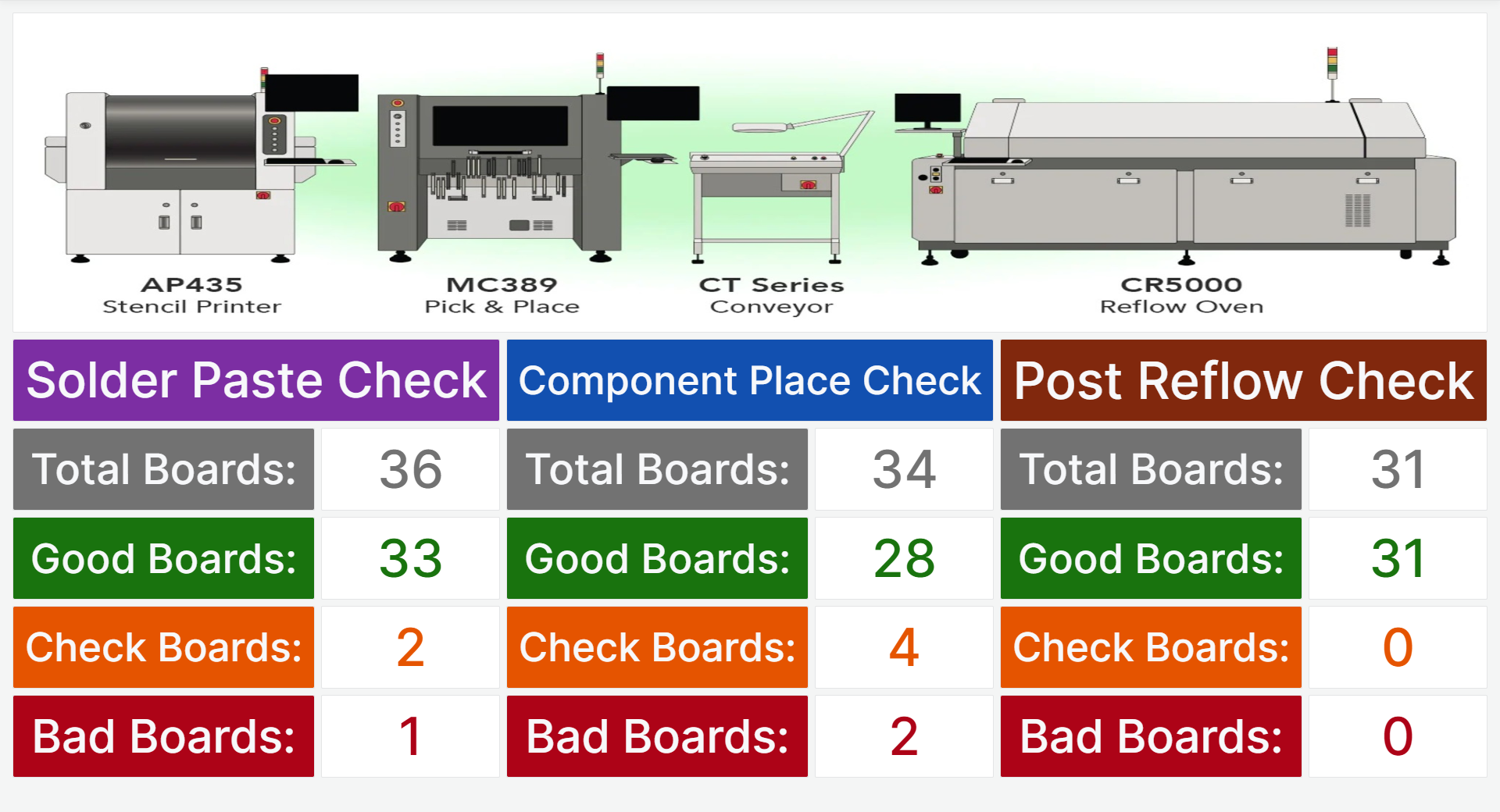

The images captured are analyzed in real-time for anomaly detection to determine quality and yield.

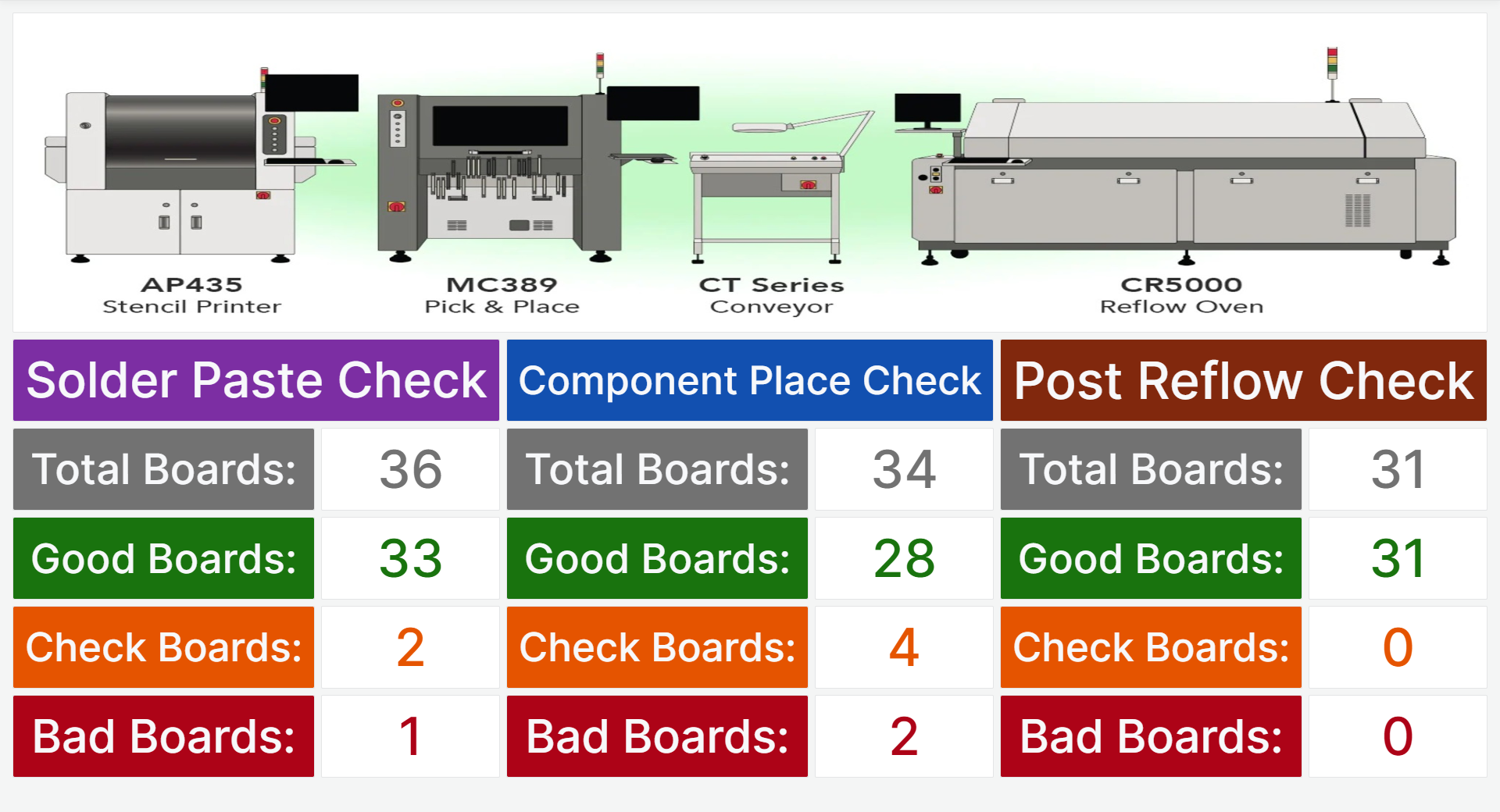

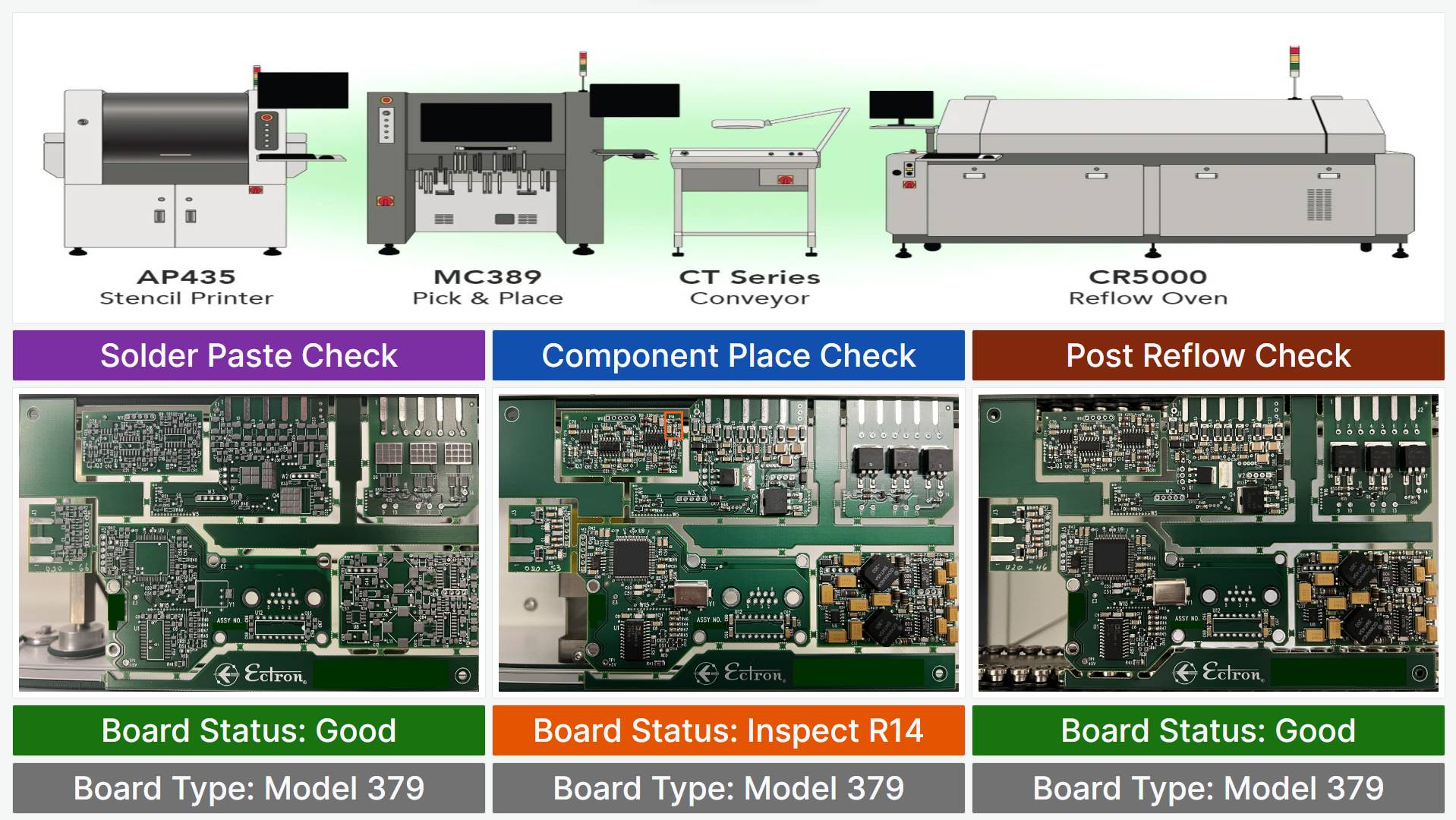

For example, used on an SMT-line, computer boards can be inspected post-stencil print, post-pick-and-place and after emerging from the reflow oven.

WHAT IS MONITORED

- Identify Board Deformation or Other Bare PCB Issues

- Check for Solder Bridges or Improper Stencil Printing

- Confirm Component/Parts Placement

- Idenitfy Defects Including Misaligned Placement, Missing Parts, Damaged Components, Shorts

- Reads PCB Board Number to Align with Job Number, Lot Number

- Yield Per Job

- Can be programmed to optically inspect other types of objects

DATA USAGE

- This solution aids the QA/QC process by recognizing and identifing non-compliant PCBs including pinpointing the precise location of the error(s). With accuracy of over 98%, it becomes an indispensible aid to manual inspections. For maximum effectiveness place along your SMT line to inspect bare PCB, PCB with solder paste, loaded PCB and finished PCB.

STANDARD CONFIGURATION

- 1 Intelligent Edge Node (featuring ECT-MAN-SER)

- 1 Camera

- 1 Camera Stand (w/ attachment)

- 1 USB Cable (to connect the Camera & IEN)