S nsors-as-a-Service®

nsors-as-a-Service®

Sensors-as-a-Service® is compatible with over 32,000 industrial-grade sensors from over a dozen manufacturers worldwide allowing you to monitor almost any KPI imaginable. Moreover, the data can be viewed on customized dashboards, or streamed to your ERP system or other business intelligence software.

Ectron has hundreds of available off-the-shelf solutions, all of which are customizable. Moreover, if you tell us what problem you are trying to solve or the type data you’d like to see, our engineers can design a solution that works for you. With pre-programmed hardware and hundreds of preconfigured dashboards already under our belts, Ectron’s engineering team has the expertise required to seamless bridge your OT and IT. Importantly, our design services are free, so if we can’t design a solution that fits your requirements, it costs you nothing.

What real-time information do you need from the factory floor or from the field to help you improve operations, reduce waste, eliminate production delays, confirm product quality, assess employee performance and/or reduce supply chain risk?

What if you could capture that information automatically, eliminating human intervention and, thus, human error. Fusing IoT into your daily operations does not have to be a large engineering project. With Sensors-as-a-Service®, you can bridge OT (Operational Technology), IT (Information Technology) and ET (Engineering Technology) including Artificial Intelligence and Machine Learning, for a fixed price and with a single vendor, Ectron Corporation.

Sensors-as-a-Service® is Plug-and-Play

- Installed in 1 day

- No changes to equipment or operations

- Requires no Engineering or IT staff to implement or use

- Is scalable, so you can tackle one issue at a time

- Starts at $125/month. Can be cancelled after 3 months.

Unlimited KPIs

- Confirm Production Schedule and Shipping Compliance

- Confirm Production Process Compliance for Certifications

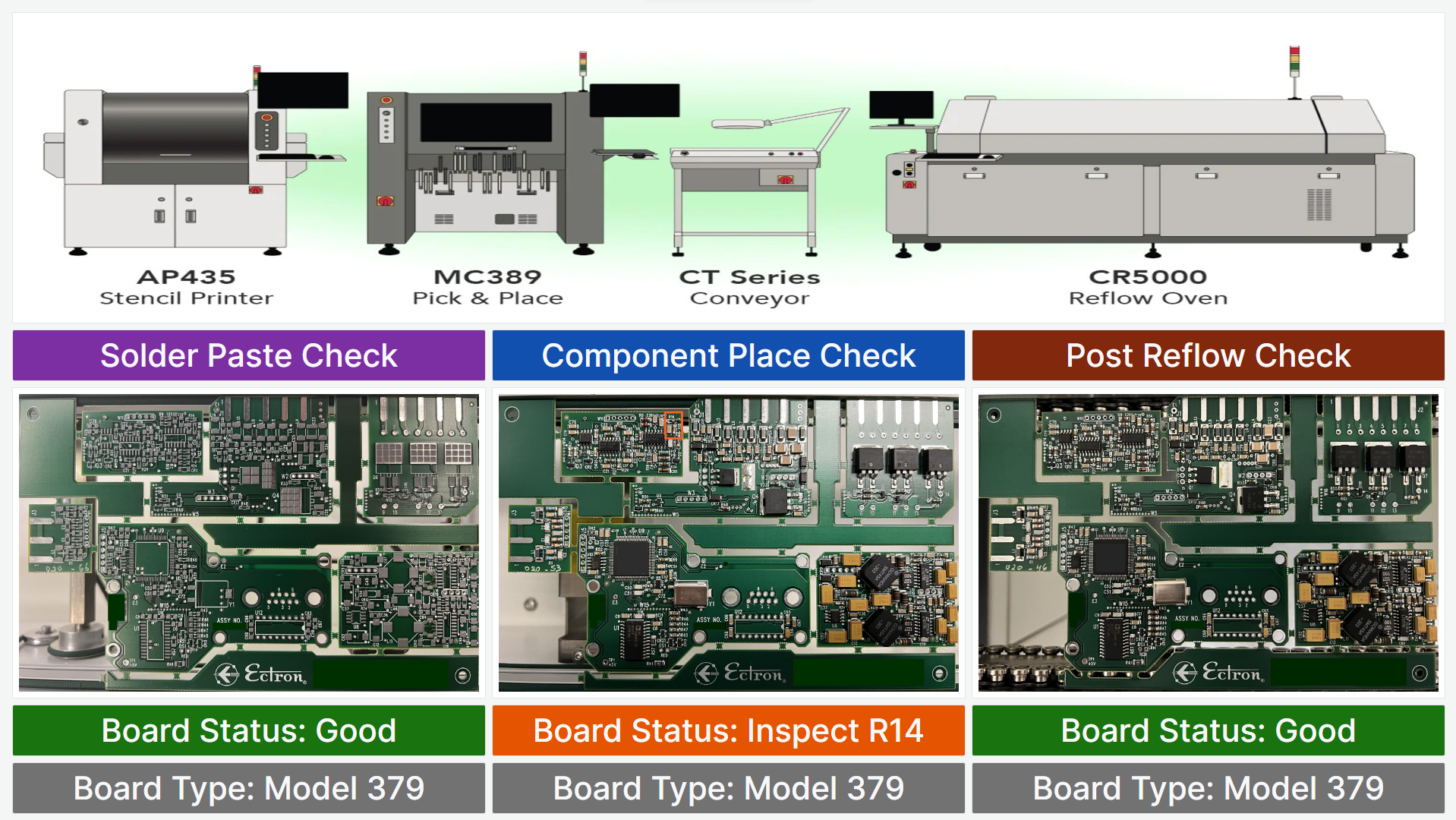

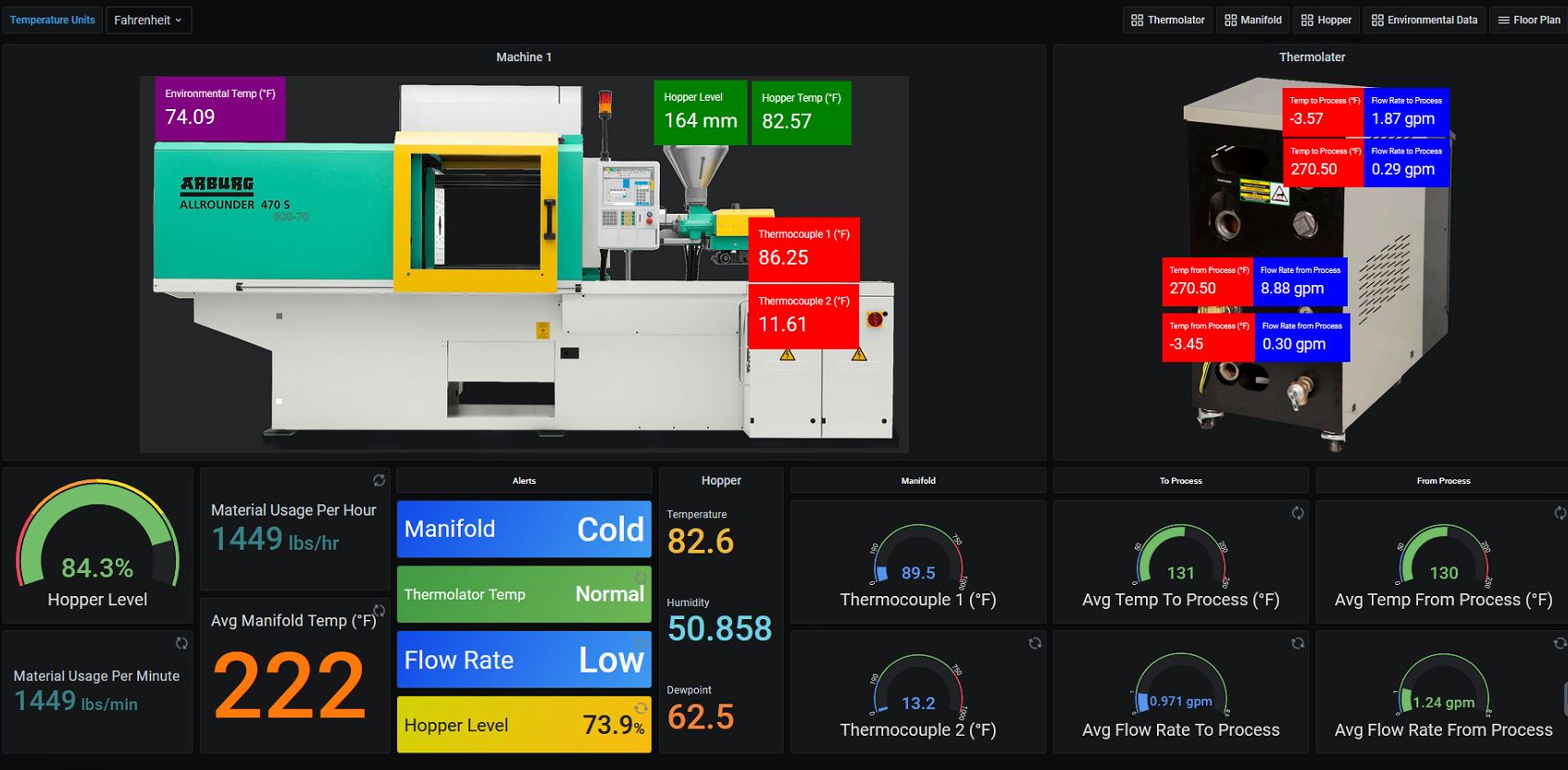

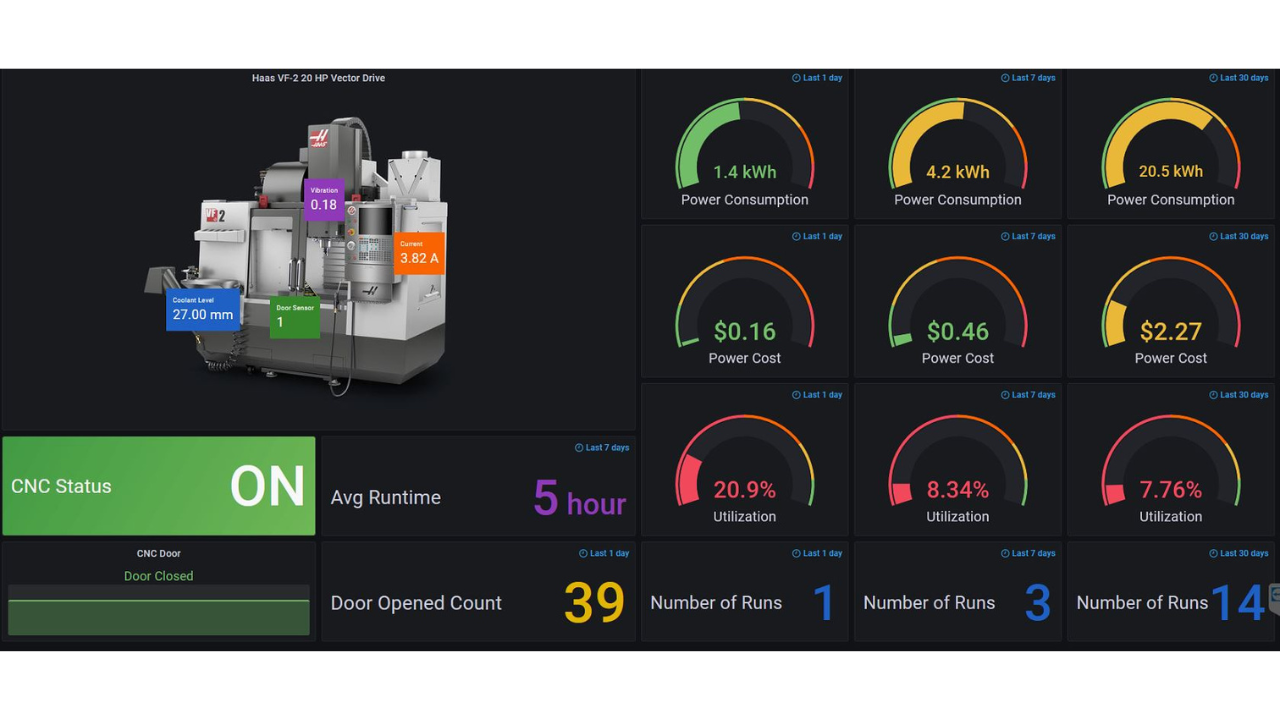

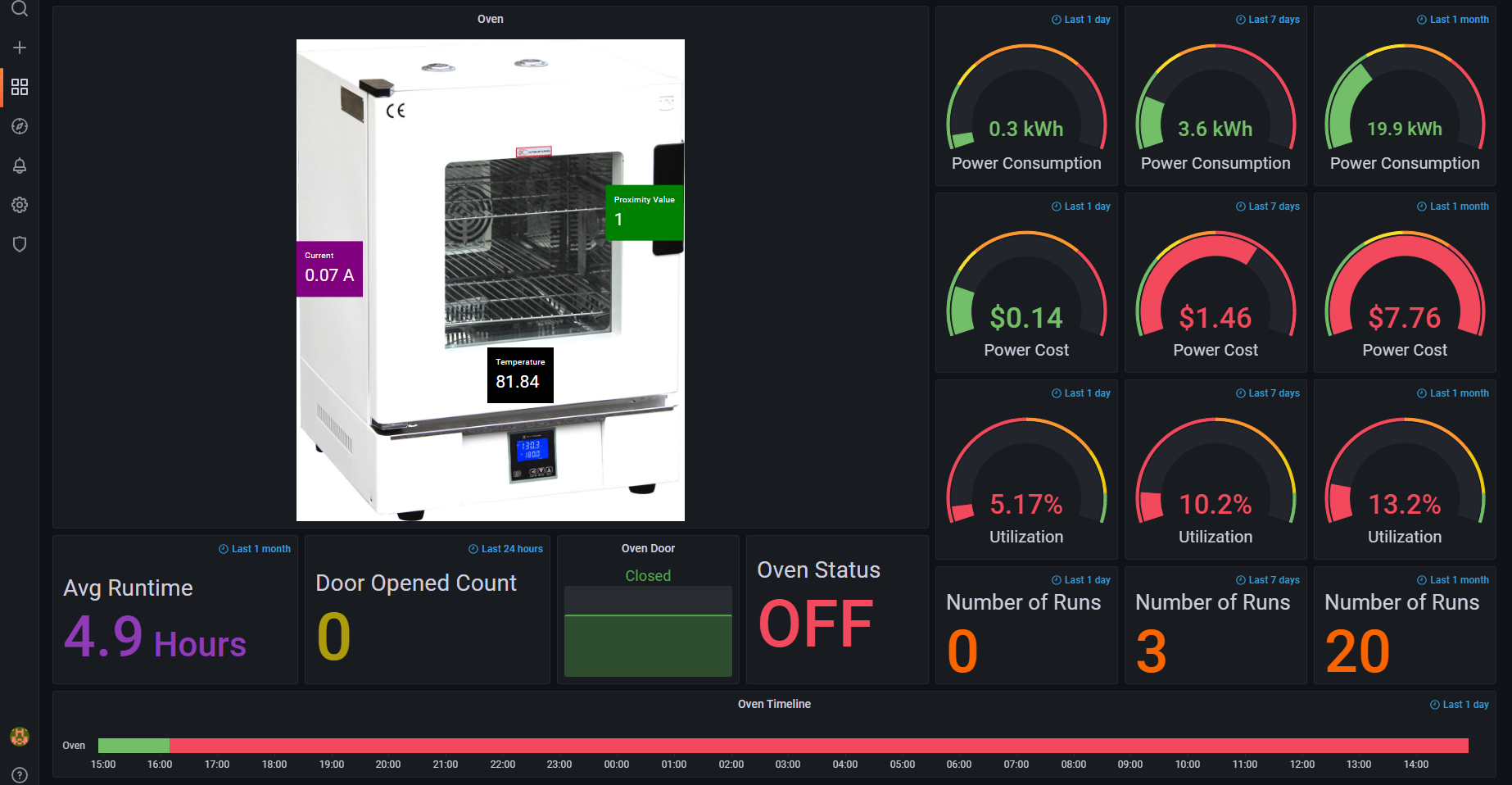

- Pinpoint Machine Deviations During the Production Run

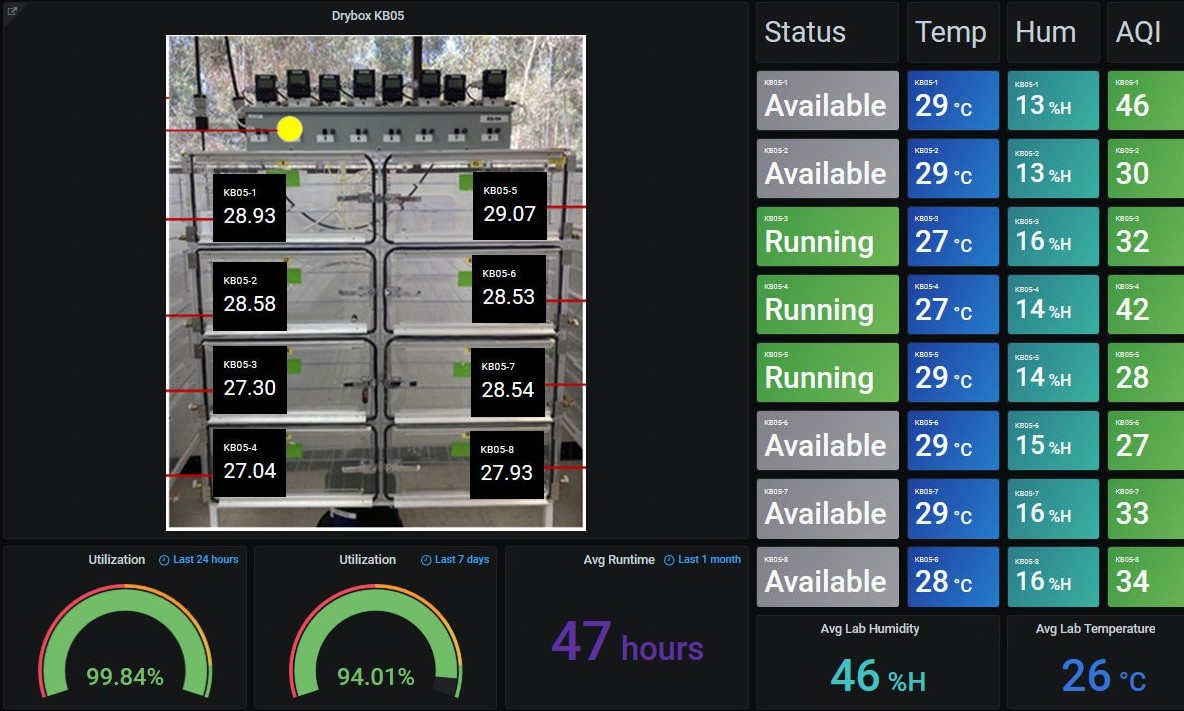

- Pinpoint Process Deviations During the Production Run

- Track Issues Causing Machine Downtime

- Monitor Ancillary Equipment/Machinery

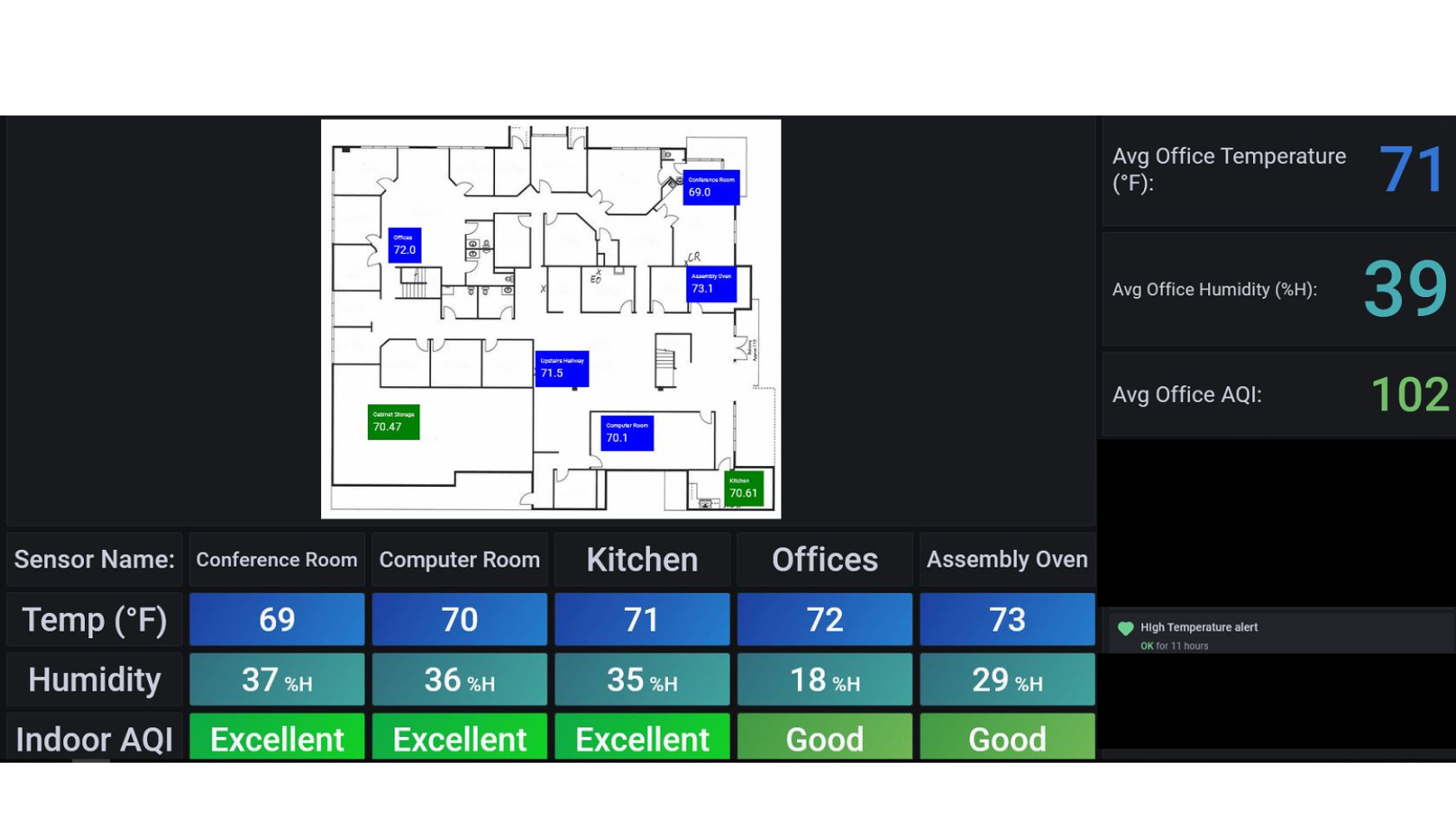

- Monitor Environmental Factors that Impact Product Quality, Machine Functionality, Employee Performance

- Identify Personnel Underperformance

- Identify Bottlenecks (Personnel, Equipment, Scheduling)

- Track Final Product and/or Subassembly Stock

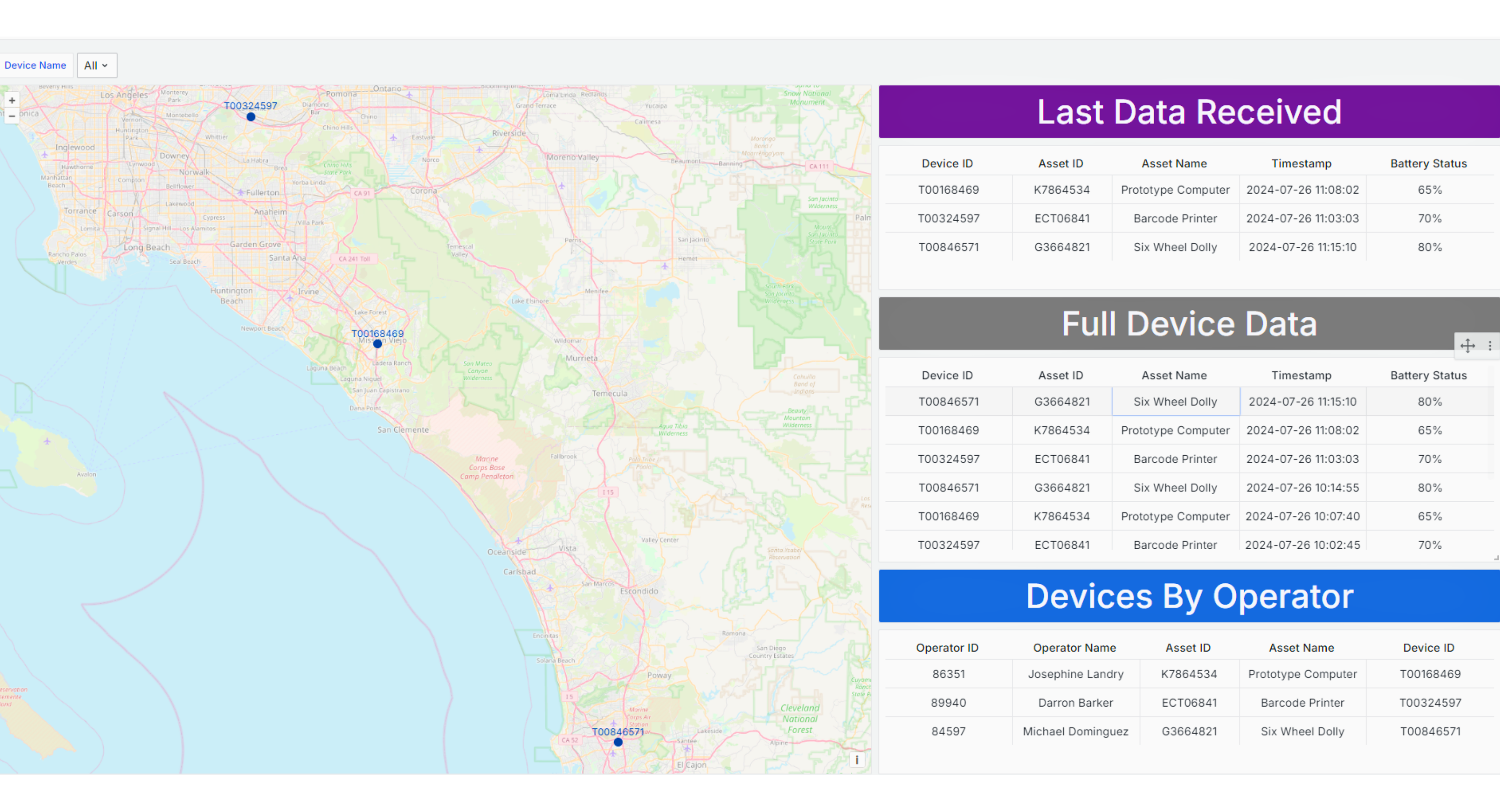

- Track Assets Globally

- Monitor Almost Any KPI with 32,000+ compatible sensor options

The Process is Simple

Step 1: Fill Out the Online Assessment Form, then Schedule a Product Consultation.

Step 2: Review the IoT Solution designed by Ectron’s team of engineers (no-cost design services).

Step 3: If you approve of the design, order the suggested IoT Kit and enroll in Sensors-as-a-Service®.

Step 4: Connect the IoT Kit to a power outlet and the internet (via ethernet port or WiFi).

Step 5: Log into your private dashboards or stream the data to your business intelligence software.

Optional Services:

- Customized dashboards

- Artificial Intelligence/Machine Learning for anomaly detection, real-time alerts, on-premises conditional action

- Integrate the data into your ERP system/business intelligence software including Microsoft Dynamics 365