SmartEYE™ offers immediate ROI by eliminating production waste and delays and identifying resource inefficiencies starting on Day 1.

Start with Level 1 (SmartEYE™ Factory Flow SaaS) to organize and analyze where waste and delays are happening.

Once you are ready, add Level 2 to one or more machines, to track machine usage, energy waste and problematic machinery.

If one or more machines are experiencing routine downtime, graduate to Level 3 so you can pinpoint downtime and product quality issues at the machine-feature level, as well as implement predictive maintenance. This is how the multi-billion-dollar enterprises run lean, and now all of this technology is available to manufacturers of all sizes.

How Well Do You Know Your Factory?

- Is the production schedule being met?

- Do we have all of the components and subsystems ready for a final product production run?

- How can I gauge employee efficiency?

- How can I incentivize employees to do thier best every day?

- How can I ensure consistent product output?

- How can I pinpoint exactly what went wrong in the process when the output isn’t as expected?

- How can I pinpoint machine profile deviations in real-time?

- When is the best time to perform maintenance on my equipment?

- Should my machine maintenance schedule differ for different aspects of my machines?

- How do I track energy efficiency?

- Can I confirm production compliance for certification programs?

- Is it possible to get real-time factory-floor data sent to my ERP, MRP, MES or other business intelligence software solution?

Answering These Questions Require Real-Time Data From The Factory Floor

LEVEL 1:

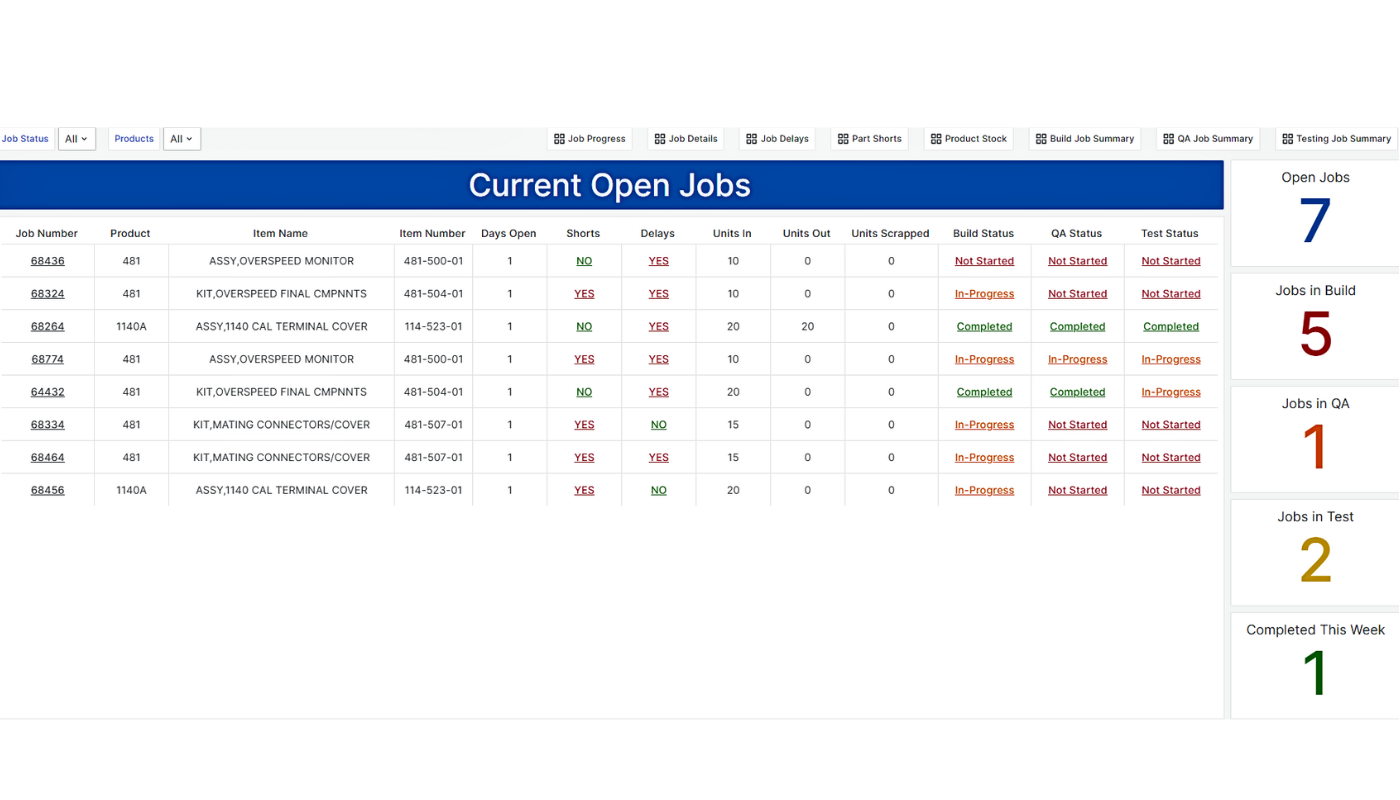

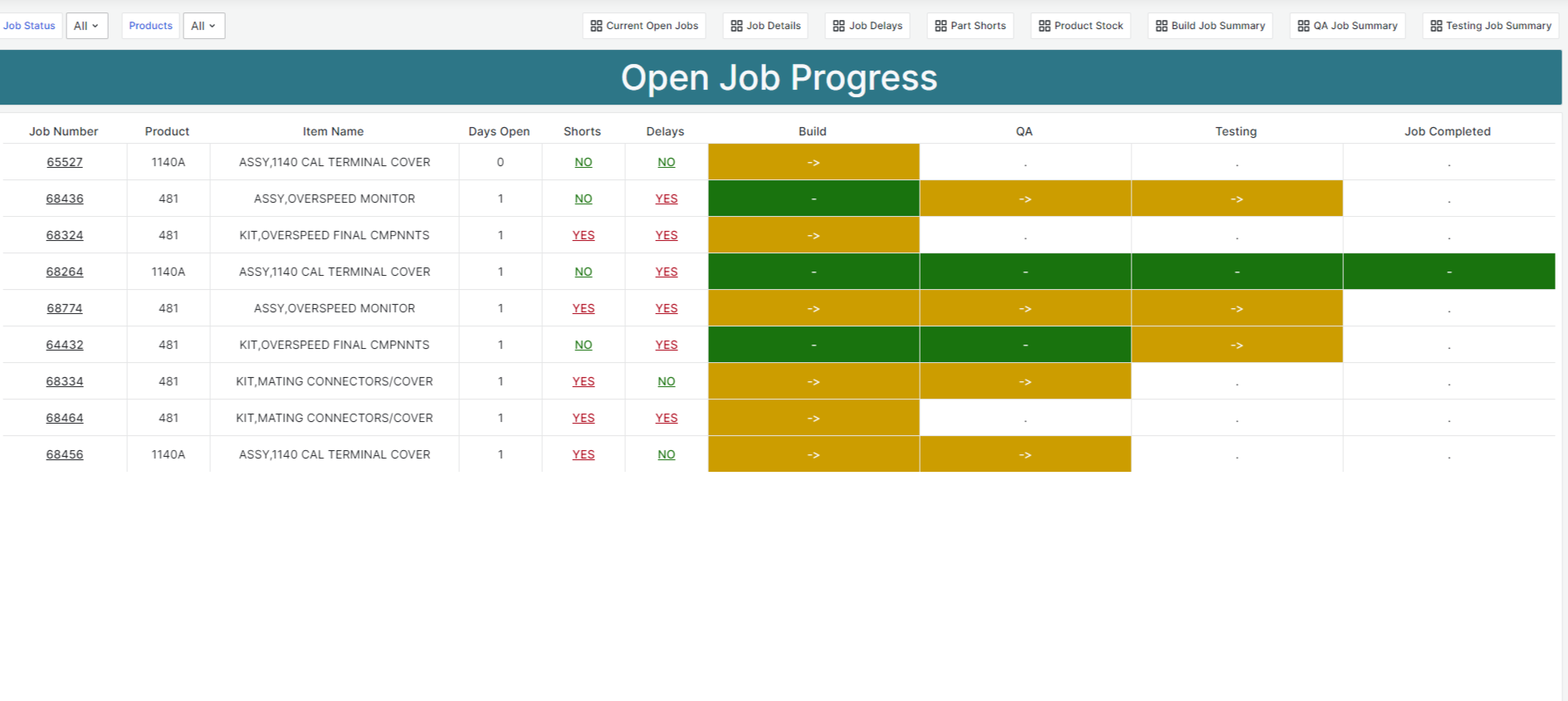

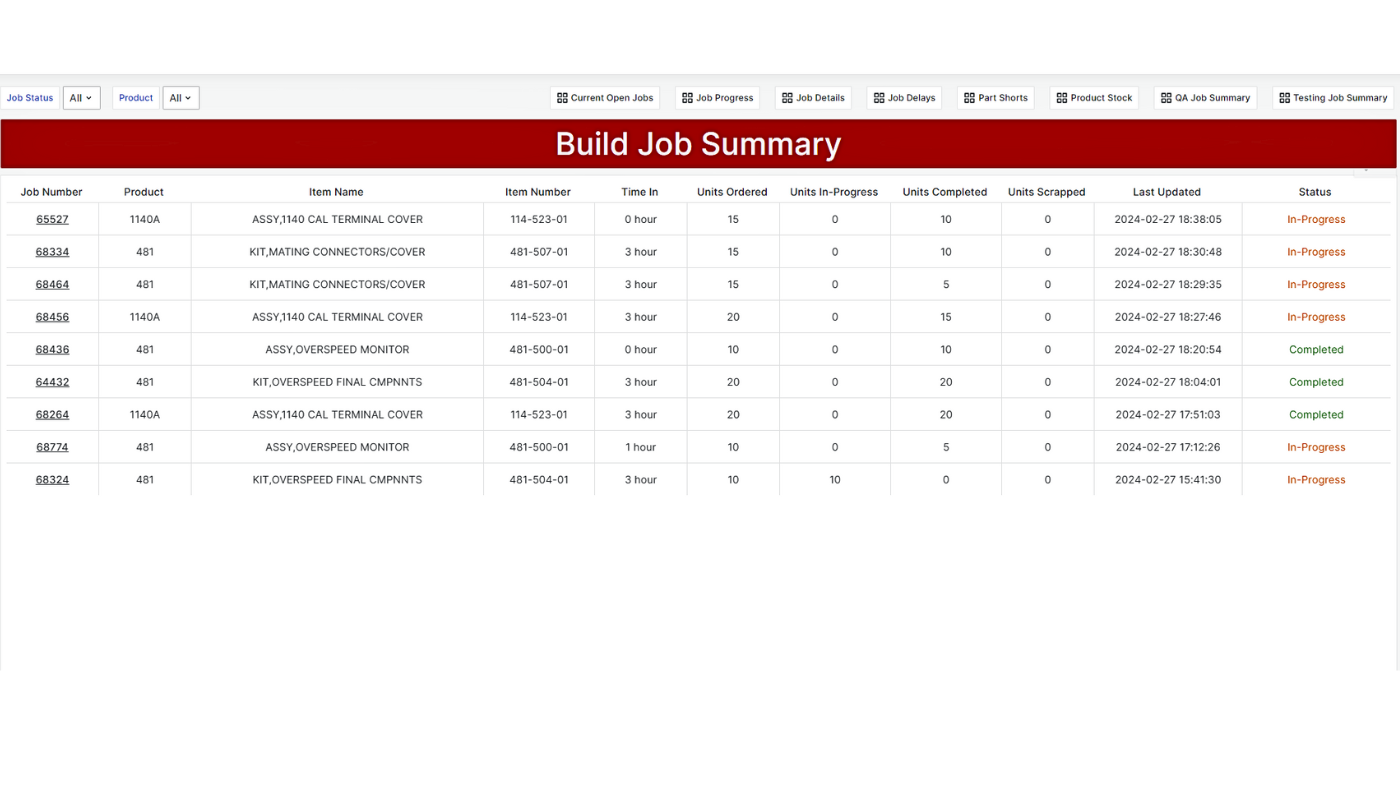

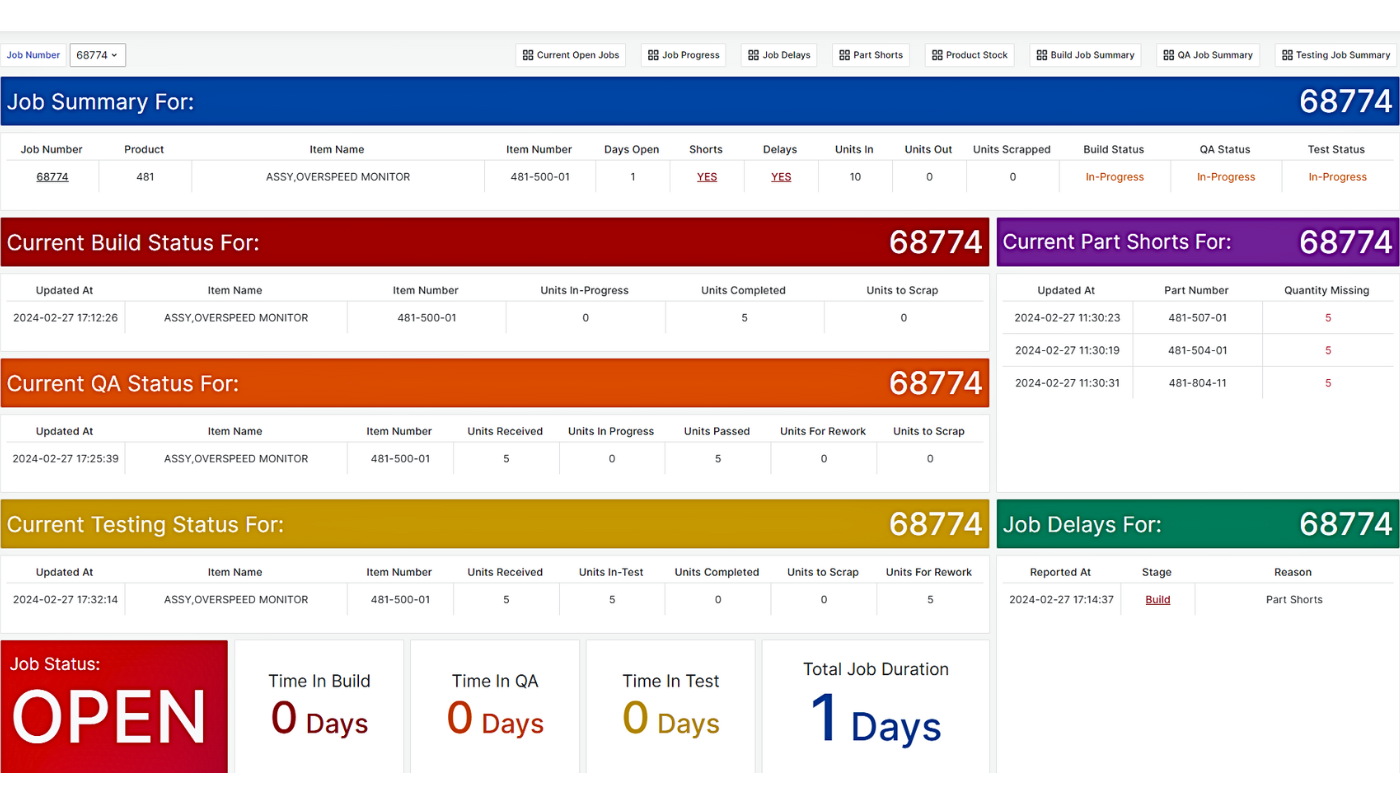

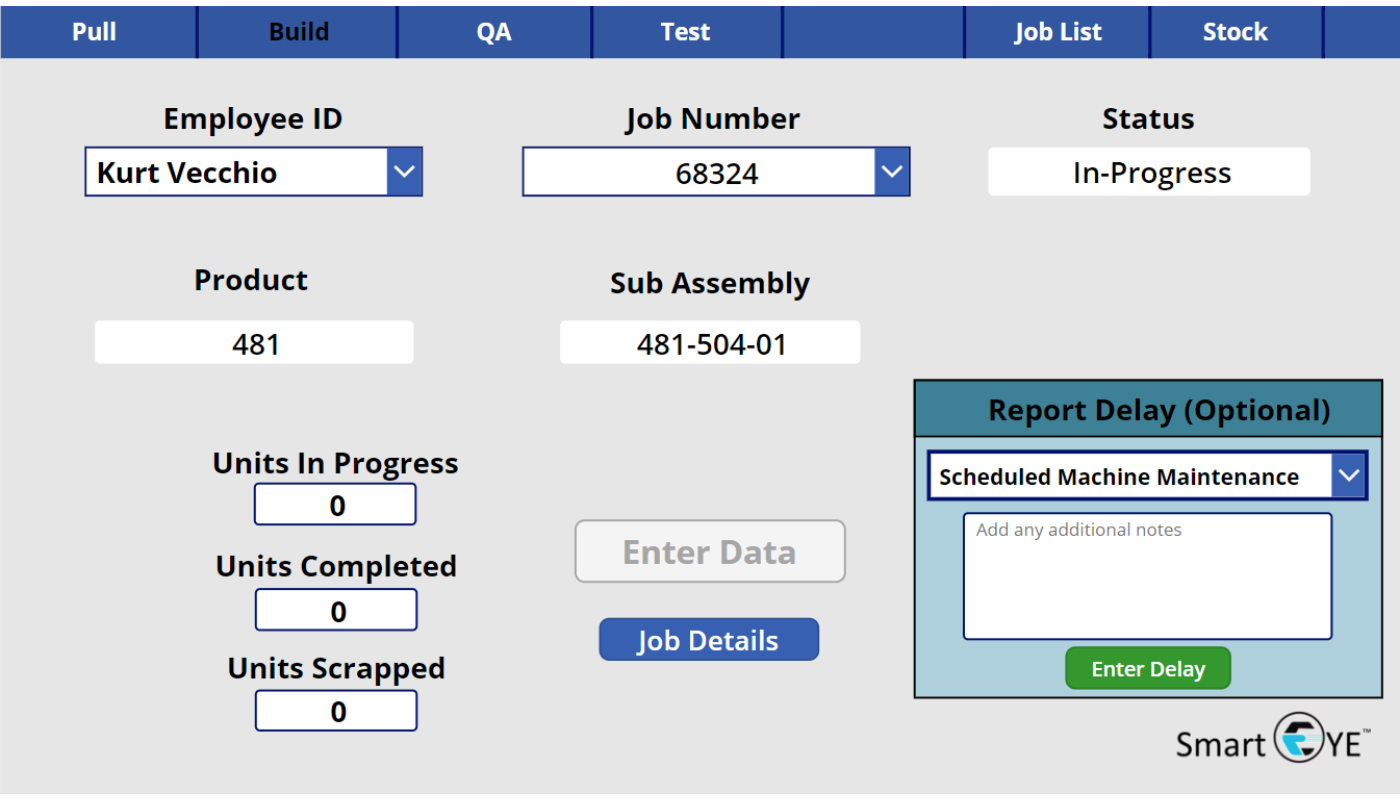

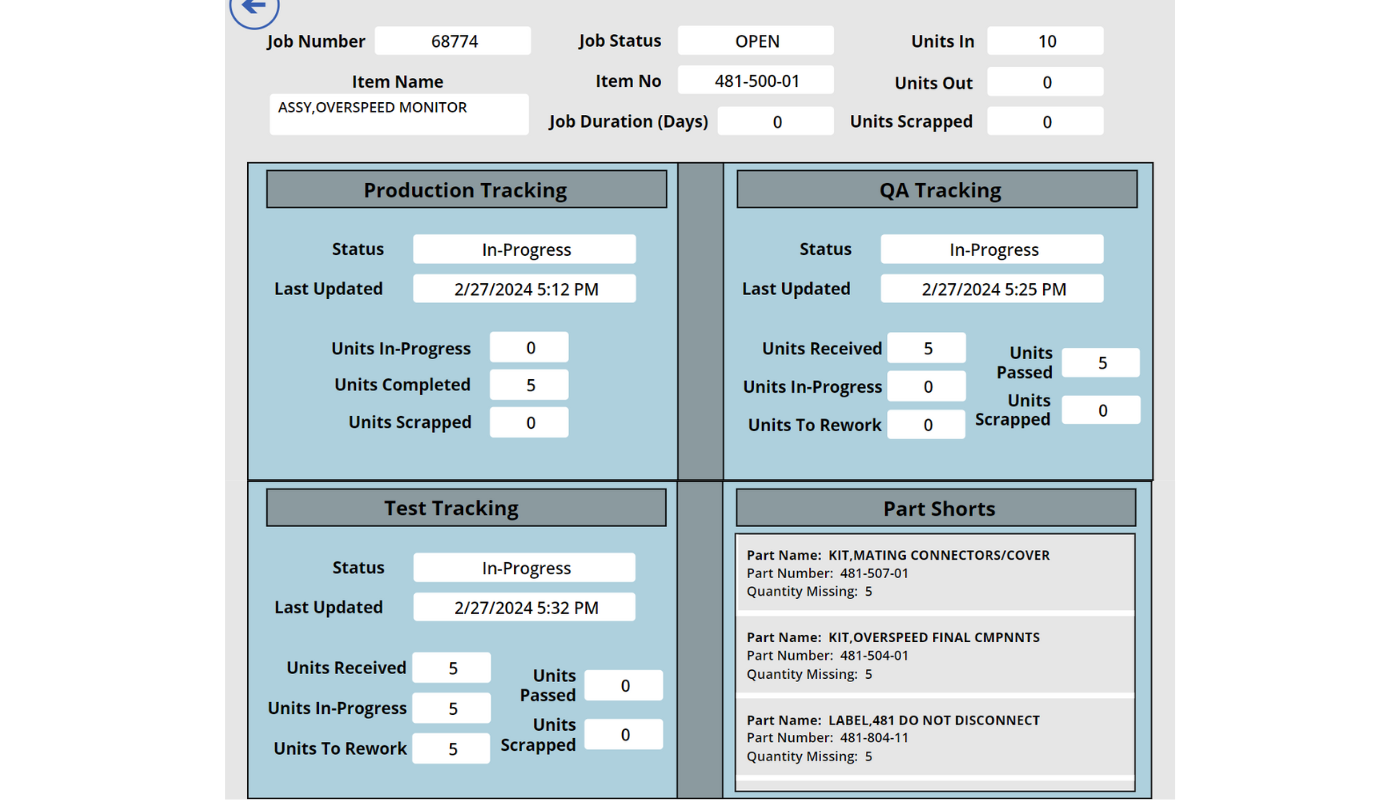

Track Production Progress, Resource Efficiency And BOM Shortages, All In Real-Time

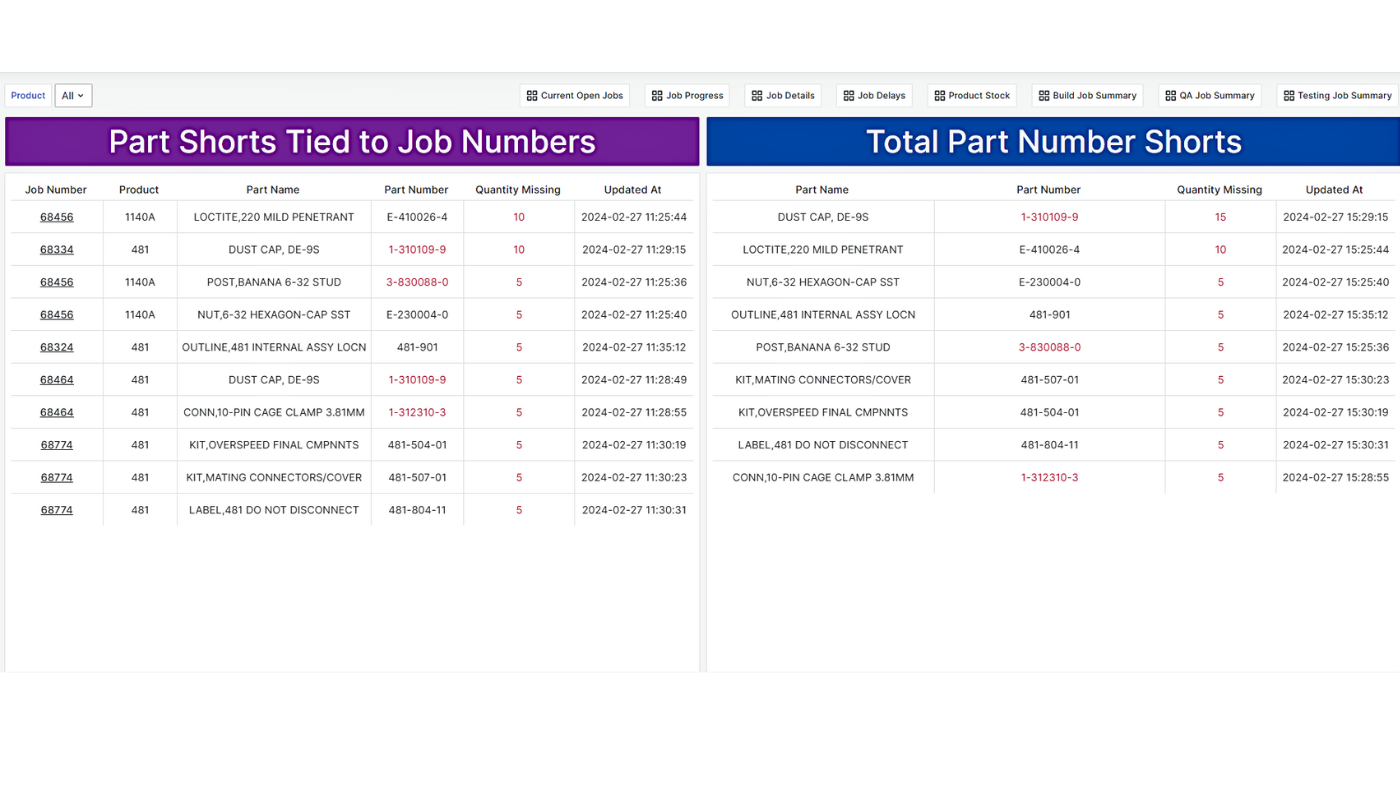

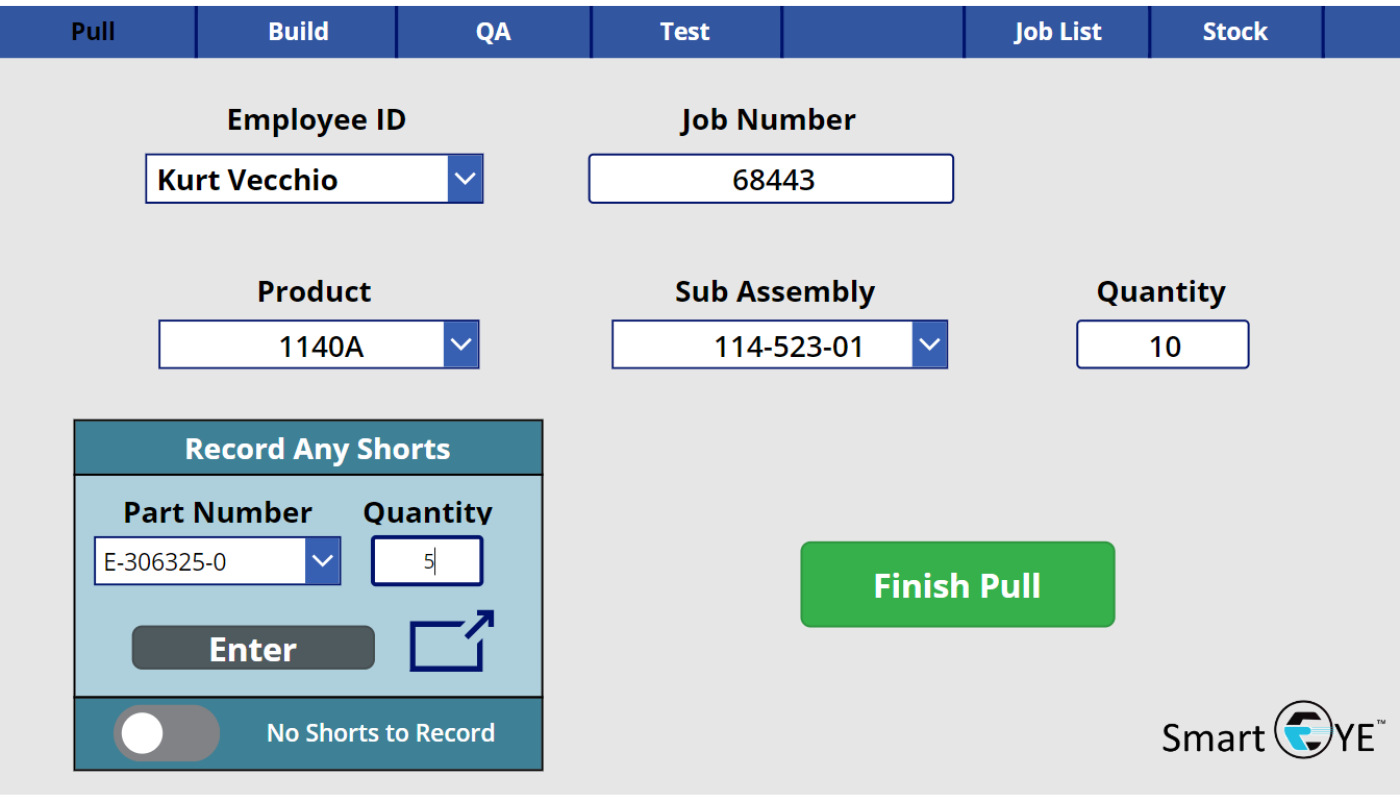

- Identify BOM and Subassembly Shortages Before a Production Run

- Confirm Production Schedule Compliance

- Identify Personnel Underperformance

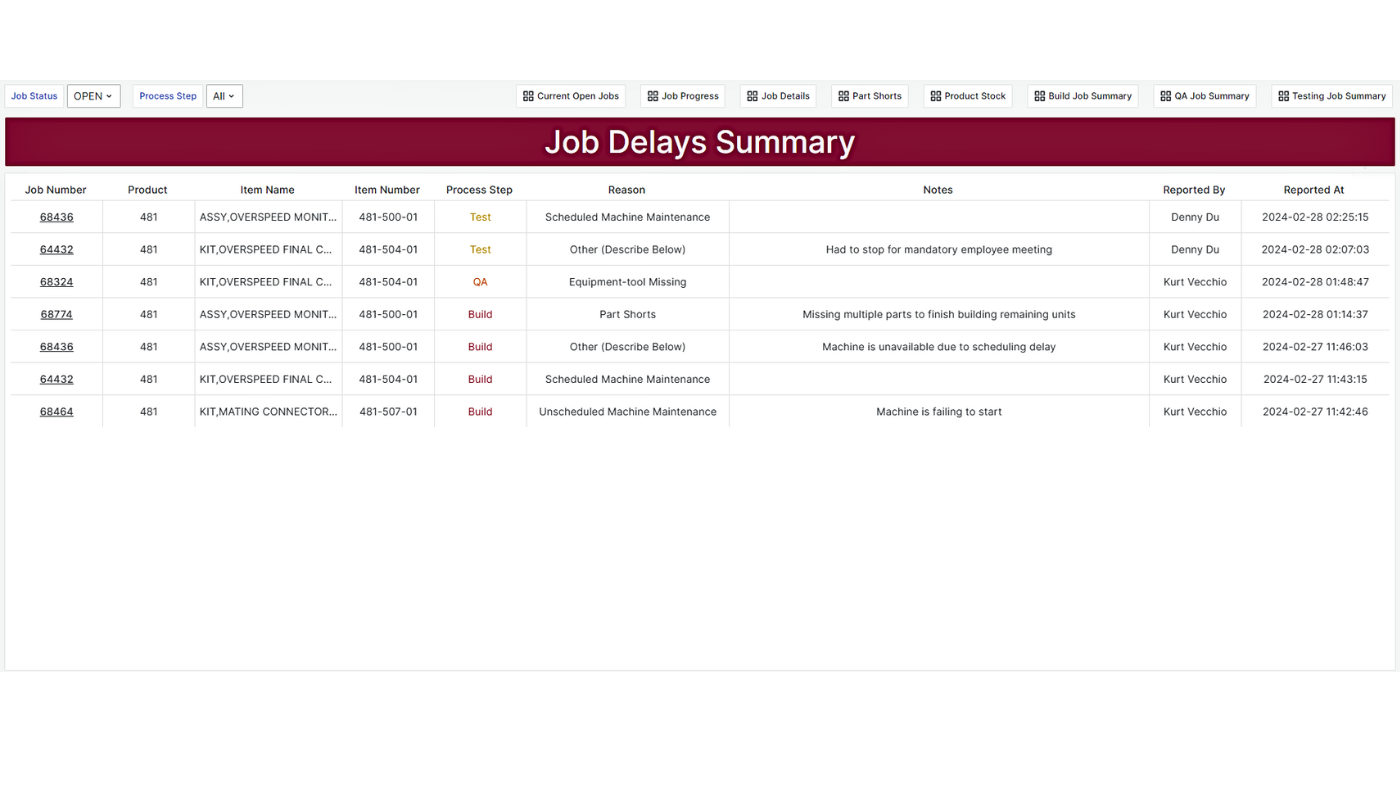

- Identify Bottlenecks (Inventory, Personnel, Equipment, Scheduling

- Track Issues Causing Machine Downtime

- Track Final Product and/or Subassembly Stock

- Confirm Production Process Compliance for Certifications

- AI Capabilities

- Instant Access

- Customization Available

- ERP and BI System Integration Available

LEVEL 2:

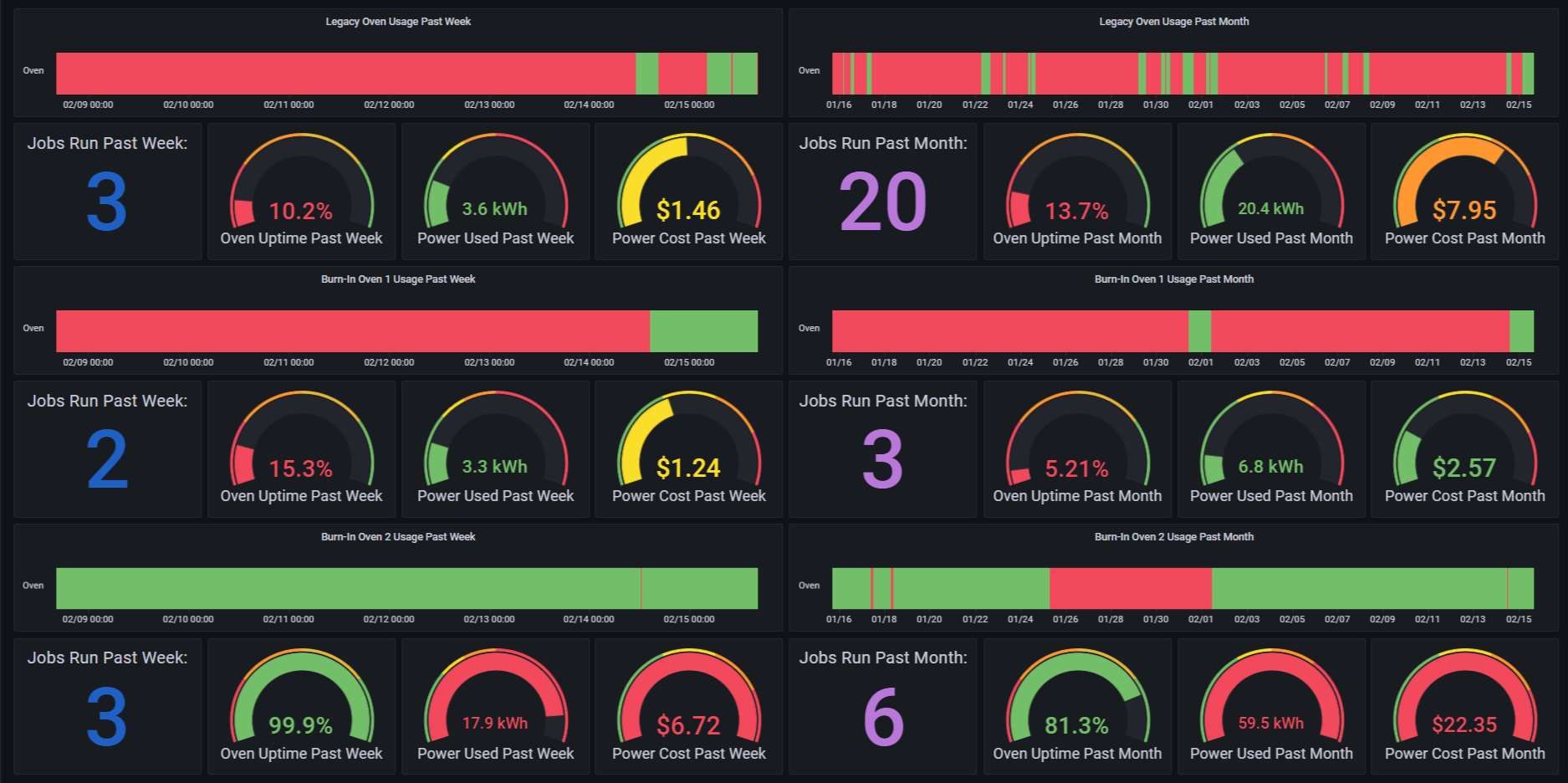

Track Production Progress, Resource Efficiency, BOM Shortages, Machine Usage, Machine Uptime/Downtime And Energy Cost Per Machine, All In Real- Time

- All of the Level 1 Benefits (with Instant Access after self-installation of machine-attached clip-on device)

- Schedule Machine Usage Optimally

- Identify Which Machines are Costing the Most Money in Downtime

- Track Machine Downtime and Resolutions

- Compare Machine Efficiencies with Respect to Various Products

- Compare Resource Efficiency with Respect to Various Machines

- Confirm Product Cost in Terms of Energy Usage

- Data Analytics on the Edge or the Cloud

- Machine Learning and AI Capabilities

- Customizable

- ERP System and BI Software Integration Available

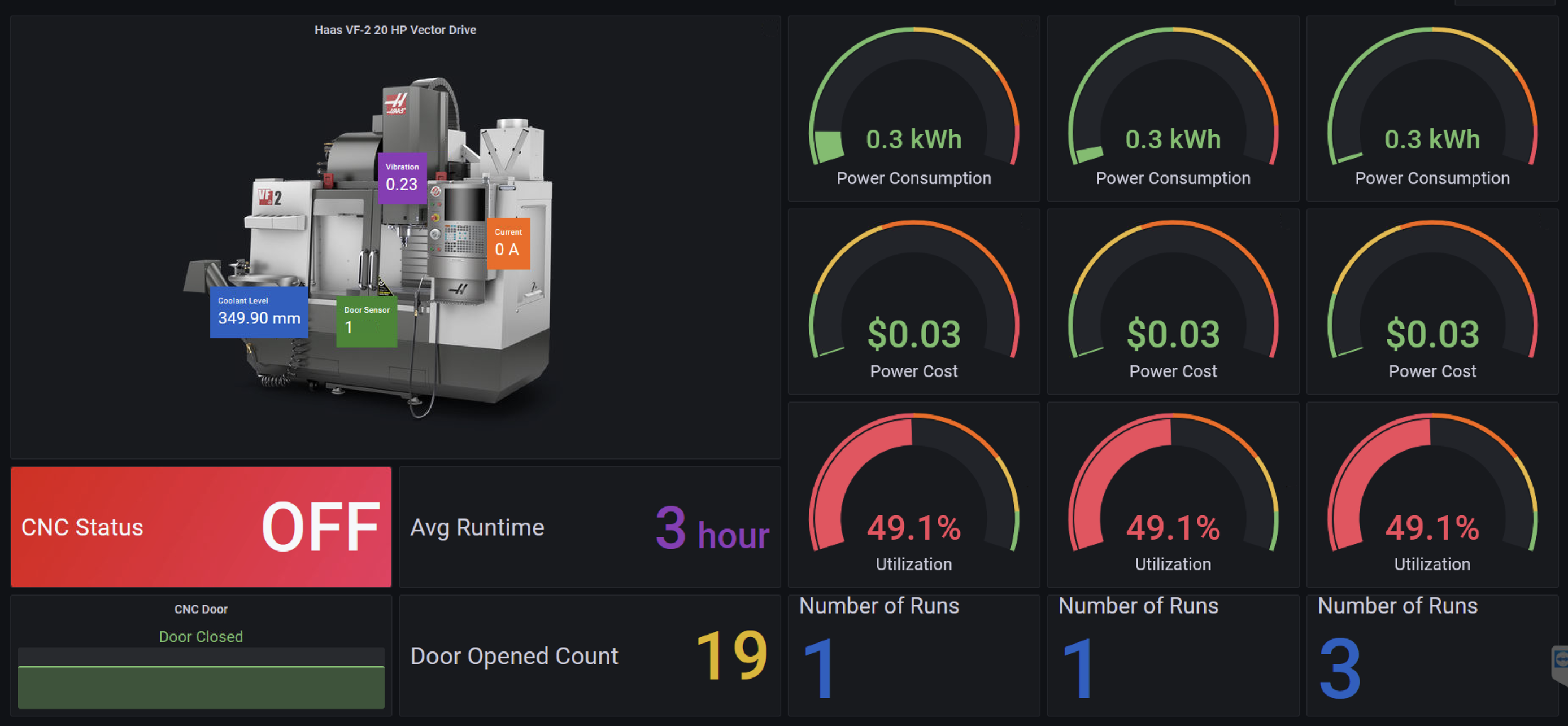

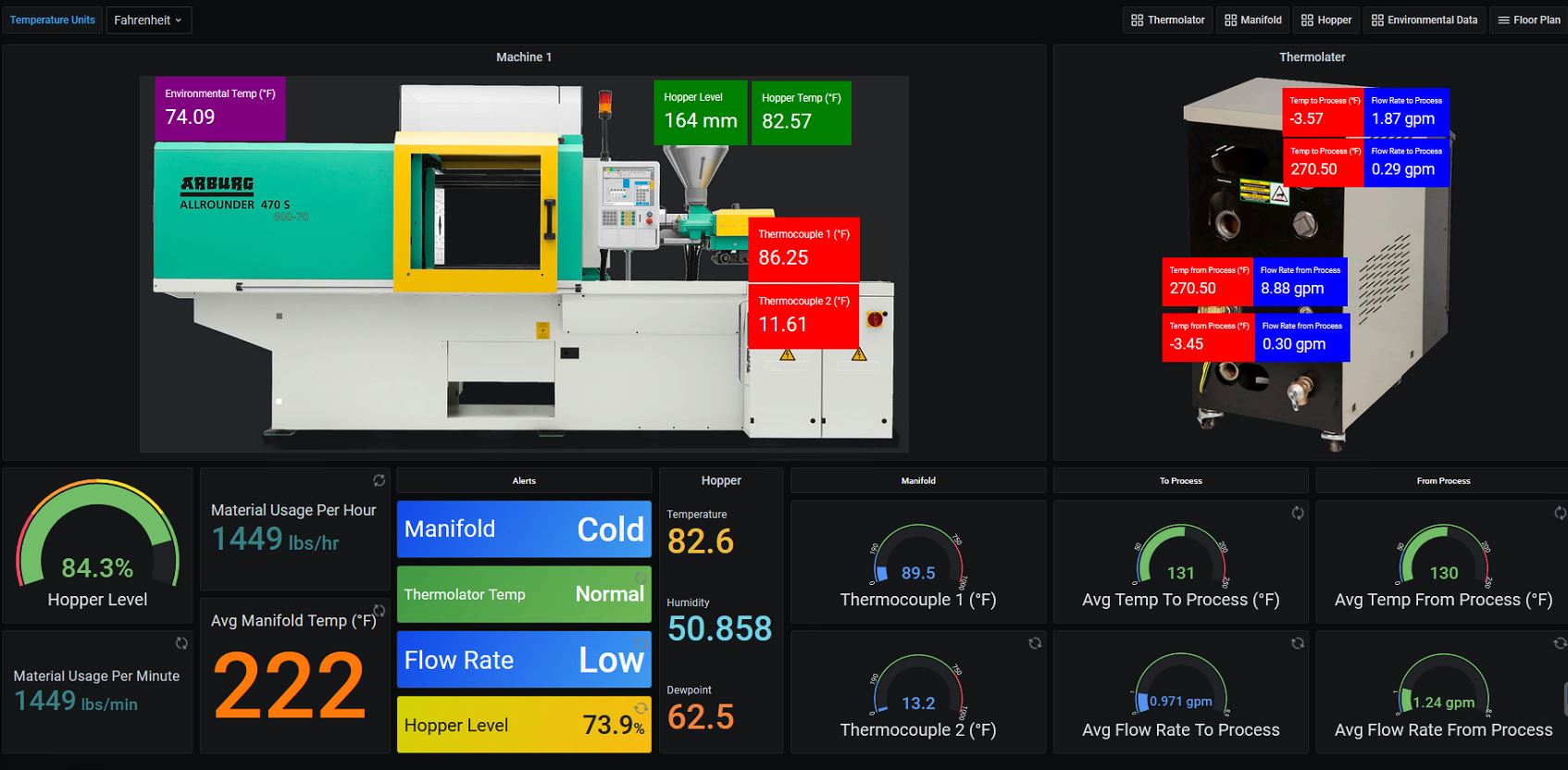

LEVEL 3:

Track Production Progress, Resource Efficiency, BOM Shortages, Machine Usage, Machine Uptime/Downtime, Machine Functionality (For Profile Deviations And Predictive Maintenance), Product Quality, Energy Cost Per Machine And Environmental Conditions Affecting Product Quality And/Or Machine Functionality, All In Real-Time

- All of the Level 1 and Level 2 Benefits (with Instant Access after Ectron install, which takes 1-day)

- Determine the Cause for Machine Downtime by Monitoring Machine Feature Data

- Receive Alerts For Machine Profile Deviations (before they impact Product Quality)

- Monitor Machine Profile Deviations and Connect to Machine Downtime for Predictive Maintenance

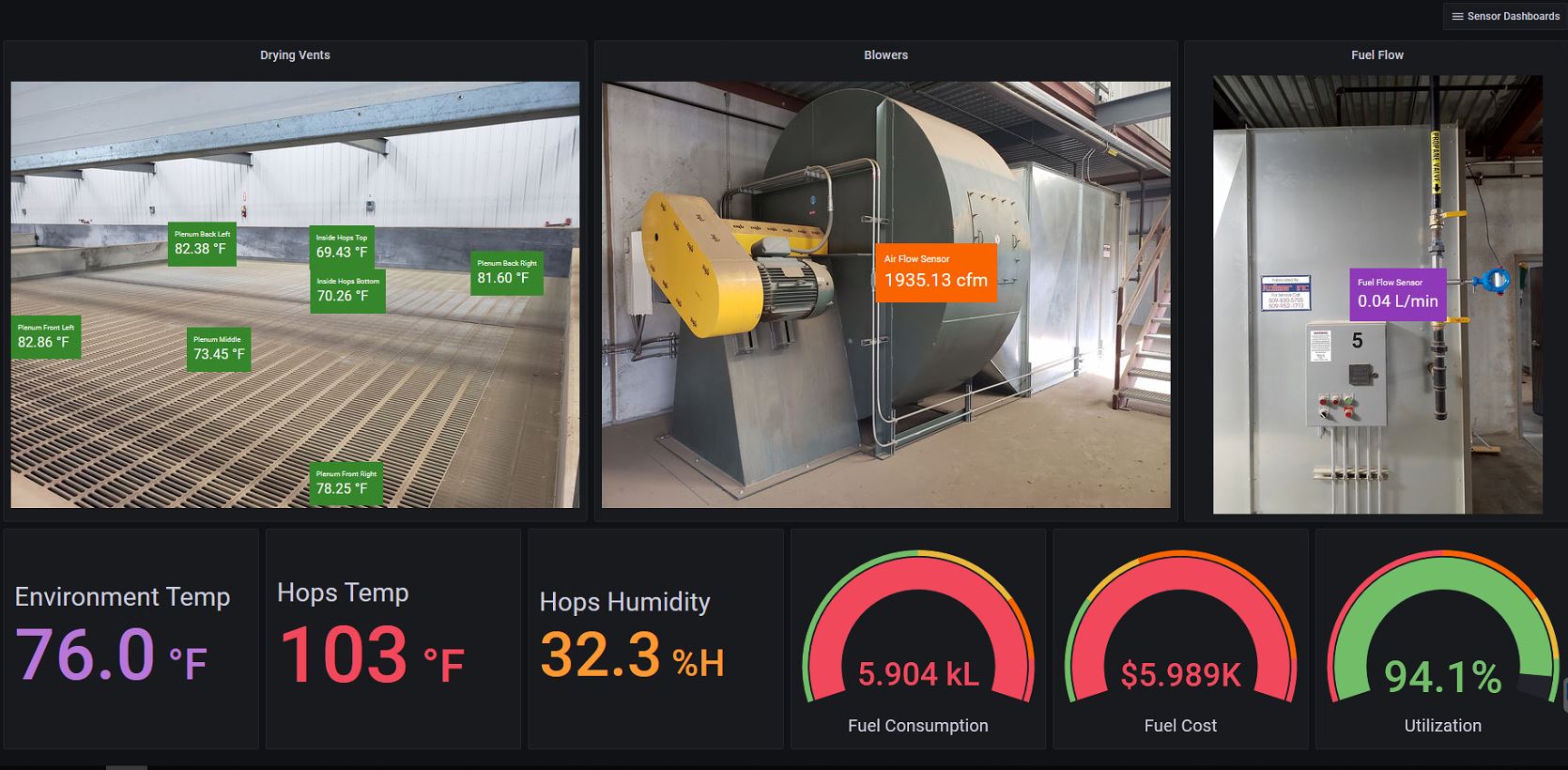

- Monitor the Impact of Environmental Conditions

- Near-Unlimited Data Analytics: Machine Learning/AI Capabilities, Compatible with Over 40 Industrial Protocols

- Tell us what problem you are trying to solve, what data you need to solve it and we will create a customized SmartEYE™ solution.

- Customizable

- ERP System and BI Software Integration Available

What Will I Need To Deploy SmartEYE™?

All you need is SmartEYE™ and a computer for entering data and viewing reports

- No Changes to Your Equipment

- No Changes to Your Processes

- No Interruption in Production

- No Internal IT Staff Required

USE CASES

SmartEYE™ can be deployed in any industry. Check out some of our current deployments.